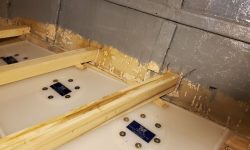

To begin, I had to get ready for Jason, the upholstery contractor, who was due later in the morning. For his patterning purposes, he’d asked me to simulate the ceiling in the v-berth, which would add 3/8″ to the existing shape and which he needed for his bevels and edge patterning. I quickly ripped four, 6″ wide pieces of 3/16″ plywood to a length approximating that of the sides of the berth, and tacked these in place–two layers per side–to give him the effect of the ceiling. Then I cleaned off the settees and, after taking a moment to pare away the excess bungs I’d installed, vacuumed everything clean for his arrival.

Once he was done with his work, I got back to work on the paint in the v-berth, lightly sanding the primer and then cleaning the area, including the head and hanging locker overheads. Then, I applied the first coat of semi-gloss white finish paint to all these areas.

I laid out the numbered staving strips from the two after bulkhead so I could see what I had and remember how they were arranged. There was one piece from the port side that had shattered upon removal, but I had some extra pieces I could use to fill in for it. In any event, I wouldn’t use all the existing staving because the upper cabinet layout was different now, so there was some room for manipulation of the existing pieces as needed. I planned to get to these installations soon.

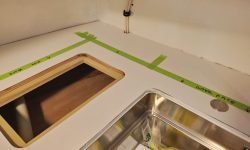

In the galley, there were still upper cabinets to be built, and some additional details, and now that the port side was reinstalled I could get down to some proposed layout. I marked out some basic lines with masking tape to show how I’d been envisioning the cabinets, with the outboard (starboard) side flush with the edge of the small countertop behind the stove, then the after section running about 6-1/2″ forward of the aft bulkhead, or the maximum possible to pass behind the faucet. The fixed upper cabinet would end just shy of the removable panels on the port side, as shown, and in that space, I proposed a semi-fixed (but removable) cabinet of some sort designed to fit around and hold securely the owner’s choice of plates and cups, and that sort of thing. It would also be possible to install something of that nature outboard of the stove, even if it ultimately overhung the countertop by a bit.

The owner had sent me pictures of a nice plate rack that fit in a corner, like the back corner of this galley. In this case, space seemed a little tight with the existing hatch in the countertop, which hatch provided access to the large storage area beneath, but might be possible. The shape of the hull here was also angled inward thanks to the tumblehome, so as the height increased, it would push a shelf further inboard.

Om the port side, a storage unit would obscure the countertop hatch directly beneath, but could avoid the nearby hatch for the garbage receptacle. Something to be built here would be easily removable as a unit.

Finally, a new possibility was something directly outboard of the stove, where there was nearly enough space, but the cabinet here could be “cheated” out a bit past the existing countertop edge with no ill effects to the stove.

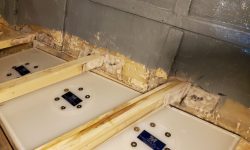

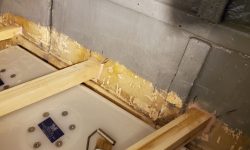

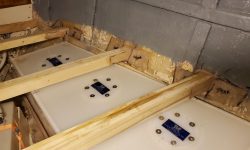

I spent some time determining what I needed to mill for trim in the main cabin, as getting the various pieces milled and started for installation was high on my list, and while I was in the area I made a new pattern of the space above the refer so I could either modify the existing lid to fit, or, if needed, build a replacement. When I built the lid, I must not have factored in enough of a reduction to make up for the hinge space, since now the inboard edge of the lid hit the nearby countertop and didn’t close. So goes the reality of even careful planning. It was late in the day, and after marking the existing countertop with the cutlines I decided it was a “fresh in the day” kind of cut and left it for next time. I didn’t know how it would go cutting with the Formica in place, but I’d give it a try since it was a relatively minor modification.