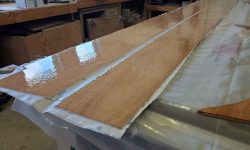

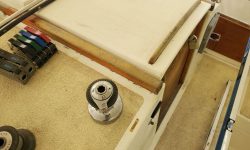

I began by lightly sanding the epoxy coating on the mast step bulkhead, transom, and aft seat bulkhead to prepare them for assembly. Then, after some minor layout and hole-drilling to accommodate the stitching wires on the main and mast step bulkheads, I installed these in their proper positions with a few wires through the bottom as directed, keeping them properly aligned with the marks at the centerline. There was a small learning curve on how best to twist the wires tightly without breaking them, but I quickly got used to the process as time went on.

Next, I laid out the pair of #1 hull panels and secured them to the main bulkhead and mast step bulkhead; tabs on the bulkheads fit into slots in the panels. Each location required drilling a few holes to accept the wiring: one at the bulkhead, centered on the tongues and a bit above, and two on the hull panel, one on each side of the bulkhead location. While I secured the wires tightly at the main bulkhead to hold the panel properly positioned, I kept the wires loose at the forward bulkhead for now; they’d be secured later.

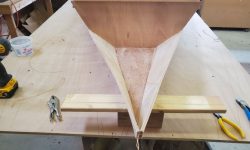

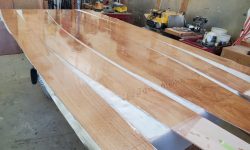

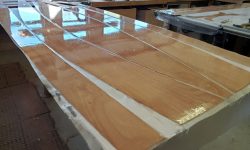

Next, ensuring that the alignment hash marks on the bottom and the two hull panels remained in line throughout, I began at the main bulkhead and, working alternately on both sides and fore and aft as well, stitched the panels to the bottom, using about every other hole to start. I worked my way nearly to the forward bulkhead, and a good ways aft, then filled in the stitching locations between those I’d done to begin with.

At the stern, I used a piece of line to pull the hull panels together and close the gaps till they met the bottom panel, then added wires there and filled in the remaining wire locations running forward to hold these panels in place.

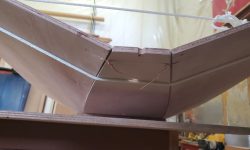

Now I worked at the bow to pull the panels tightly together and complete the stitching. I found it useful to use the line to help pull the panels together, in addition to a longer wire suggested in the manual that helped pull the panels together near the stem. I snugged up the wires where the panels met the mast step bulkhead, and pre-installed wires through the various holes in the stem itself.

Using a combination of wiring force, hand pressure, and the control line further aft, I pulled the leading edges of the two hull panels together at the stem and tightened the wires, or stitches, from bottom to top as I went. This was the most complex curvature in the hull, but I found that it went more smoothly than anticipated. Once the stem was wired together. I installed the stitches to secure the hull panels to the bottom from the mast step bulkhead forward, oompleting the assembly of the first two hull panels.

To continue, I installed the aft seat bulkhead, with its glassed face point forward, and aligned it with the marks on its aft edge, which pointed to the edges of the bottom panel. Then, I installed the transom to the inside edge of the hull panels, wiring it as directed and aligning it on the centerline. At this point, I also added a couple stitches to the main bulkhead to close up small gaps on either side where it met the first hull panels.

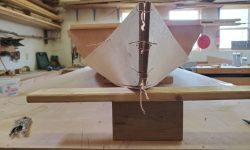

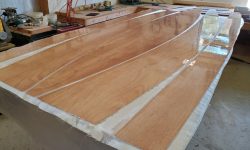

With the foundations in place, I loosely secured the pair of #2 hull panels on each side, holding them with loose stitches at aft seat bulkhead, where tabs fit into slots in the panels, leaving the forward ends to flop as they saw fit.

Then, I wired the panels to the mast step bulkhead–again loosely–before starting again at the main center bulkhead and stitching the panels to the tops of the first row of panels, running forward and aft a couple stitches at a time and alternating sides. As I neared the bulkheads, I tightened and fully secured the wires there. As I worked aft, I found it useful to pull the panels into the transom with the piece of line.

By the end of the afternoon, this left me with the panels fully secured to the tops of the panels beneath, from the transom to the mast step bulkhead, but still ahead lay the final wiring to the transom, and then at the stem ends, which is where I’d pick up next time.