Monday

I spent the day working on the remaining deck hardware, starting with the winch bases.

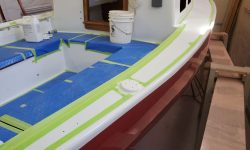

I continued with the furler cleat, located to starboard on the small molded riser on the sidedeck outboard of the coamings.

Next: The two mooring cleats on the poop deck.

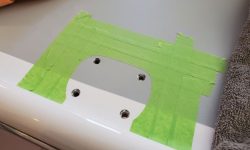

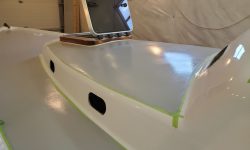

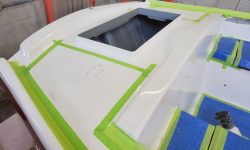

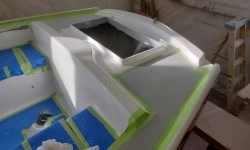

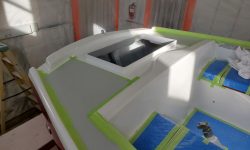

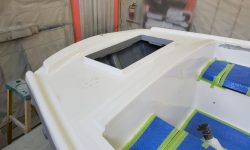

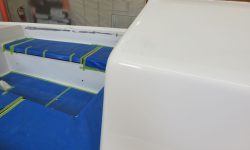

The main halyard led aft from the mast to a winch on the cabin top to starboard of the companionway, and would pass through an opening in the new dodger. Because the dodger used a track to secure the forward end, the line slot would be some distance above the deck, roughly equivalent to the top of the plastic track. To ensure that the line cleared the track as needed, I built HDPE risers for the forward turning block, winch, and cleat, raising each about as high as the top of the dodger track.

Afterwards, I installed the halyard hardware on its new risers.

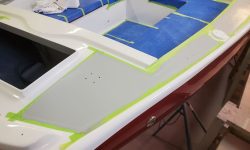

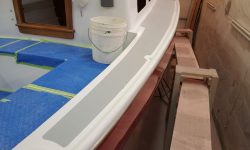

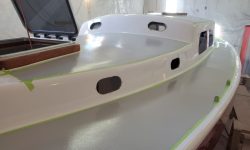

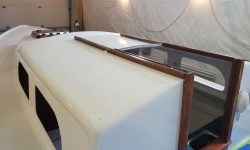

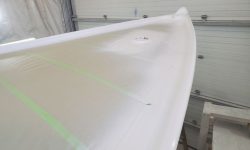

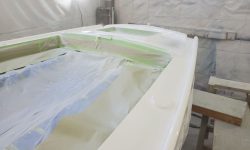

To reinstall the mast step, I began by drilling up through the holes in the mast beam below, then finished preparations above deck and reinstalled the step on its existing riser, which the owner had installed previously to make up for cutting an equivalent amount off the base of the mast to remove corrosion. The rebuilt deck was perhaps marginally thicker than the semi-original deck before, and I found I had to increase the depth of one of the recesses in the mast beam below to allow me to thread on the nuts and washers, but once I got that worked out the installation proceeded without further incident.

I almost had time to reinstall the wiring conduit through the deck near the mast step, but I needed to double-check its original position before drilling the new hole, and didn’t want to hurry the task, especially after the mast step took so much longer to install than I’d originally anticipated. So I’d finish that final piece of hardware next time before moving onto the ports.

Total time billed on this job today: 7 hours

0600 Weather Observation: 8°, clear. Forecast for the day: Sunny, 20°