November 3, 2017

Steadfast 8

Friday

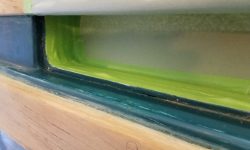

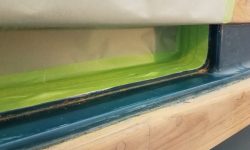

I finished up the masking at the freeing port openings, applying additional tape from the outside to seal off the gaps between the paper and the tape inside the port. I repeated this process for all six openings, but I’ve randomly selected two to display below

Next, I covered the bulwark strips with paper to keep out dust (immediately) and overspray (later). For the moment, I held back the tape at the edges and the bottom of the strips, since any tape immediately adjacent to the hull was likely to be damaged during sanding operations, but once the bulk sanding was complete I’d come back and mask off the final edges of the bulwarks.

Forward and aft of the bulwark area, I masked beneath the caprails, following the caulk and paint line that already existed there, and finally, at the stem, I closed off the plastic and masked off the stem fitting and rollers to complete the job.

The owner, in contact with a previous owner of the boat, had learned that the current paint system was a well-known one part polyurethane paint. This was good information, but alas, it meant that despite the existing coating seemingly passing all the compatibility tests, I’d now have to remove it all before refinishing with a two-part system–a possibility I’d always entertained, but had hoped not to require.

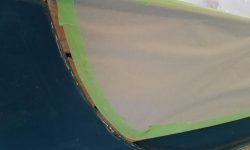

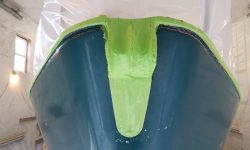

Starting at the starboard bow and working aft, I spent the remainder of the day sanding and removing the old paint more or less down to the gelcoat substrate (the boat was apparently brown from the factory). As I started, I explored cautiously till I could determine the various paint layers and what the actual final substrate was. I worked through 40 and 80 grits on the sander, not taking it too far with either grit and leaving spots of old primer that the next rounds of finish sanding (with a different tool and sanding grits) would take care of in due course, all to ensure that the hull remained fair. I removed the boottop and bottom paint to a point roughly 2″ below the apparent actual waterline so I could strike anew these lines later.

There was a lot of hand work required, not only at the usual places like around the stem casting and the forward deadlights, but particularly in the bulwark recesses and freeing ports, where the exposed hull area was too narrow for a tool. Because of the extensive nature of the hand work on this boat, I took care of these areas as I went along, rather than leaving them all for later while concentrating on the bulk hull sanding. This helped to spread out the hand work so it didn’t overwhelm. By the end of the day’s work, I’d made it about halfway down the hull–the “big half”, since the bold bow had much more surface area than the after portions of the boat, and to the aft end of the second freeing port.

Total time billed on this job today: 7 hours

0600 Weather Observation: 60°, mainly cloudy. Forecast for the day: Clouds, maybe a sunny break, then showers, high 60s.