November 12, 2020

Skeedeen Phase 6-34

Thursday

As is my wont, I started the day with a brief round of sanding on the companionway doors and hatches to prepare them for a second coat of maintenance varnish. I also sanded and varnished again one of the cabintop handrails, as this one had worn strangely the season before and I wanted to get some extra coats of varnish on it now.

Armed with new fasteners, I continued with the swim platform installation, securing the three angle brackets to the transom with “bo-koo” sealant and the new #14 fasteners.

With the brackets in place, I could install the platform, securing it from beneath as needed with new fasteners through the brackets and into the teak. This really finished off the new transom. New scupper flaps to cover the scupper openings would come soon; they were up with Renee being faux-finished to blend with the transom.

Next, I reinstalled the three sets of stainless steel half oval moldings on the rubrails and stem. I secured these with new fasteners and butyl sealant.

In the cockpit, I quickly wired up the new stern light, mating it with the wires left from the original installation.

In the engine room, I picked up where I left off several weeks earlier when I’d just finished painting the space. Now, I reinstalled the large wire/hose bundle along the starboard side of the engine room as it had been originally, and a smaller bundle to port as needed. I reinstalled the battery storage trays and left the negative engine cable loose pending the engine reinstallation sometime later.

I led new 3″ vent hose from the hull vent boxes and into the engine room, generally following what had been there originally and clamping the hoses to the boxes in the narrow spaces outboard of the cockpit. There were three intake vents, plus the blower vent to starboard. At the owner’s request, I replaced the electric bilge blower with a new version in the process. ONce the large hoses were in place, I reinstalled a couple vent hoses that I’d removed for access before.

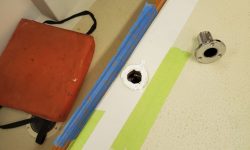

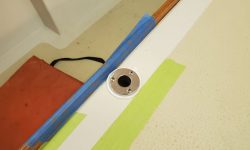

With the project winding down, I turned to one of the last items on my work list, which was to re-secure a set of socket mounts on the engine box, which held a removable tubular and wooden backrest that the owner used. The sockets, which I’d installed some years before, had become a little loose, so I removed them and, after cleaning up the old sealant, tapped the screw holes for the next-larger fastener size (#10). The larger fasteners fit well in the socket bases after I slightly enlarged the existing holes, and I applied sealant and resecured the sockets with the new fasteners.

Total time billed on this job today: 6 hours

0600 Weather Observation: 61°, cloudy, humid (November?) Forecast for the day: Cloudy and becoming cooler, 48°