Tuesday

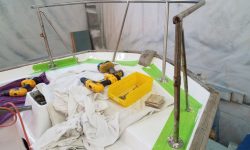

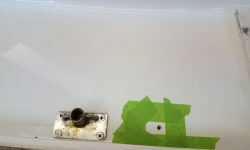

I set up the stern pulpit again and dry fit it, securing it temporarily with screws in the outer (solid deck) holes so I could accurately mark and drill the remaining holes in the newly epoxy-filled holes in the other areas. Once I’d drilled all the holes, I removed the pulpit once more and finished up the work on the new holes, tapping for 1/4″ machine screws and beveling the tops of the holes with a countersink.

With the area cleaned up, I applied sealant and installed the pulpit with machine screws, nuts, washers, and backing plates, reusing some more or less permanently-affixed fiberglass backing plates from the old installation that remained inside the steering room (two centermost stanchion locations).

I temporarily installed the bow pulpit, which was straightforward since its bolting locations were on the outboard side of the toerail flange. The pulpit looked ridiculous hanging out in mid air beyond the stem, as I had not yet built the new bow platform, but for the moment the installation served its purpose and would allow lifeline measurement whenever the riggers wanted to do it.

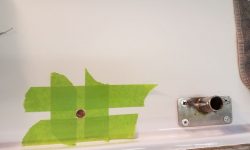

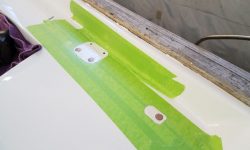

The two stanchions amidships featured built-in gate braces, and these required an additional screw. When I laid out the port side during an earlier phase of the project, for a reason that now escaped me I’d chosen not to pre-mark the hole location for the brace, so on this side I installed the stanchion (more on this in a moment) and marked the hole location, which turned out to be in a cored area of the deck, so I bored out the hole with a 5/8″ bit and filled it with thickened epoxy to prepare the hole for next time.

On the starboard side, I did have a pre-marked, pre-filled fastener location, so I could permanently install the stanchion and its gate brace now. I had gate braces for the aftermost stanchion pair as well, which formed the other end of the opening gate section, but these were separate pieces and I’d get to their installation shortly.

I had some trouble installing the stanchion tubes, which should have been a simple task, but in almost every case the fit was just a bit too tight–these stanchion bases originally came from another boat, obviously with different tubes, though the ostensible diameter was the same. In any event, fitting the stanchions required some sanding and cleanup of the tubes and especially within the base sockets before I could install the stanchions properly. This was an irritating frustration that required much more time than it should have, but eventually I prevailed, as indeed I must.

Total time billed on this job today: 6 hours

0600 Weather Observation: 12°, mainly clear/high clouds. Forecast for the day: Mainly sunny, around 30°