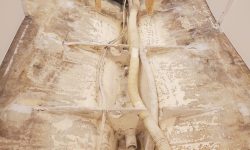

For the cabin sole support beams, I used 1-1/2″ fiberglass angle, which I cut as needed to fit the measurements I took off the top edges of the existing floors where I’d cut them. Inside the boat, I determined that the aftermost floor, located just ahead of the engine room, was the highest point when determining longitudinal level, to which the boat had been positioned early in the project. So I started here to position and install the new supports. With the first beam positioned correctly, I held it in place with two bolts for now, and moved on to the next three in turn, leveling off the previous beams in each case and temporarily securing to the existing floors with two bolts.

At the aft end, the new height was more than an inch lower than original. In this photo, where the level is resting on the tops of two or three of the cross beams, the top mark is the height of the original floors (the supports beneath the cabin sole itself); the second mark is 1″ below that, and the third mark is where the height actually ended up.

Interestingly, the new height of the cross beams ended up perfectly level with the top of the new mast step structure, a happenstance–but useful and good–occurrence.

Now I removed the four cross members and, after final preparations, installed them permanently with epoxy adhesive and two bolts each, ensuring they remained level at each location and in both directions. At the ends, I added thickened epoxy to create the basis for eventually tabbing the ends to the hull in a separate operation to happen later.

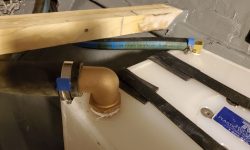

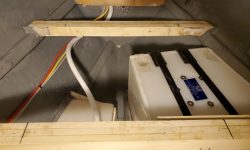

With the main four cross members in place, I continued (pirouetting around the tacky epoxy as needed) with the supports required at the forward end and around the battery compartment. This was made easier thanks to the mast step being level with the new structure, and also thus with the small forward section of sole in the head compartment. I installed two wooden support cleats on the inboard edges of the battery box, and an additional fiberglass angle cross piece between the aft side of the battery box, where I secured it with screws, and the hull on the opposite side, where I epoxied the angle in place. And finally, I added a short piece of angle on the aft side of the mast step structure, since I measured eight feet from the engine room bulkhead to the aft corner of the step, so to support a full-length sole panel on this side I needed an extra lip off the aft end of the mast step.

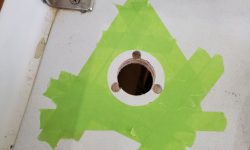

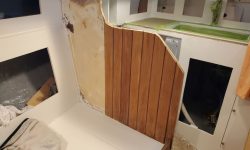

That was about all I could do for the cabin sole for now, but all the main pieces were in place and would cure overnight to allow me to continue next time. To round out the day, I tackled a couple minor tasks, including preparing a backing plate for the new padeye on the foredeck, and trimming one edge of the prefab teak handles for the galley bulkheads so that they would work in the specific situation to overlap the forward side of the bulkhead, but remain flush on the aft side. This was necessary since the existing bulkheads, with their staving on the forward sides, were thicker than the milled recesses in the teak, and also to allow the refer lid to open smoothly past any upper bulkhead trim.