Monday

Looking to make some progress even with the holiday, I started a short workday by preparing, then filling with thickened epoxy, the old hole left from the holding tank vent in the hull. The new fitting was slightly larger and I’d need to redrill the hole, so filling the old one was the easiest way to provide me with the necessary center for the new, larger hole. I expected all of the old hole, and its epoxy filler, would be eliminated when I drilled the larger hole later.

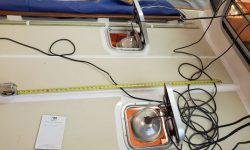

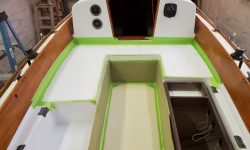

Seeking additional storage, the owner inquired about one or more deck boxes in key places on deck (aka places there might be room), and one of these was to be on the centerline forward of the pilothouse, where there was ample open space that wasn’t used for anything else. I made some initial measurements of the space to determine the possible dimensions of the new deck box. To leave clearance aft of the mast, and for the rigid boom vang, it looked like an overall length of 48″ would work (and also use the sheet goods efficiently), and by overhanging somewhat the 11″ wide raised center portion of the deck, the width could be made as needed to accommodate some of what the owner hoped to store. Height-wise, the box had to be deep enough to be useful, but couldn’t extend too high lest it block too much of the view from the pilothouse windows; the owner had suggested that roughly the height marked by the lower window frame in its open position would be OK. This was around a foot.

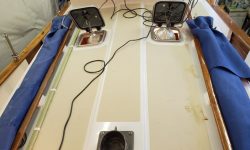

One thing the owner hoped to keep in the new box was a spare propane tank to fit the small propane locker in the cockpit. The tank was just over 12″ tall and a bit over 11″ in diameter, so these formed the basis for my calculations on the new deck box. To keep the height from growing too much and being an impediment to visibility, I thought I could create a recess for the bottom of the tank that would minimize the space required for it, as well as holding it in place inside the box. Therefore, I decided to make the sides of the box 12″ tall, and the overall width of the box 15″ to easily fit between the deck hatches, but not overhang the raised portion of the deck by to much (14-1/4″ inside width). I hoped these overall dimensions would make the box useful without being too bulky.

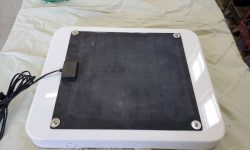

To this end, I cut to size the sides, ends, and bottom from 12mm marine plywood. I routed out a circular area to fit the bottom of the propane tank, which allowed the tank to fit within the 12″ tall interior of the box. To support the box on deck, I planned to add plywood feet to hold it just off the deck for drainage, and I planned for one of these plywood additions to reinforce from beneath the section beneath the propane tank.

To showcase the size of the box, I temporarily taped it together to hold the sides and ends in place. Once I confirmed that the box would be adequate and suit the owner’s needs, I’d start assembling, fiberglassing, and finishing the box.

Total time billed on this job today: 2 hours

0600 Weather Observation: 30°, mostly cloudy. Forecast for the day: Clouds and sun, 39°