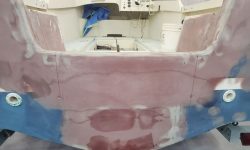

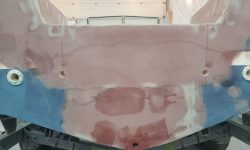

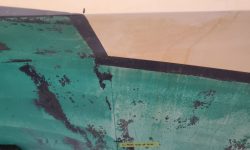

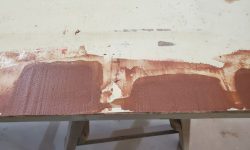

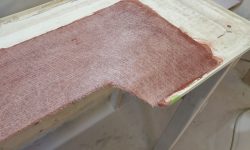

My day began, as it so often does, behind the sander controls. Working now mainly with finer grits as the various surfaces approached final contours, I began with the transom and hull sections, cleaning up the most recent round of fairing material, as well as at the now-patched engine room vent openings. This round of sanding brought things nearly to completion other than some minor inconsistencies here and there.

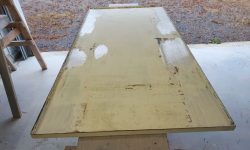

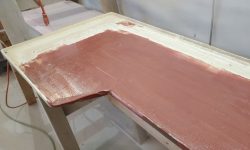

I also sanded the undersides of the livewell hatch and fuel tank hatch, smoothing the latest–and last–round of epoxy filler there, but it seems I never took a picture, perhaps because my sander started blowing up near the end. I finished the last small epoxy patch on the fuel tank hatch by hand and, after cleaning up from the morning’s round of sanding, apparently never got back for photos.

(An aside: With my discovery, earlier this year, of the apparent discontinuation of my favorite major sanding tool, the Porter Cable 7345 (previously known as various other model names that I can’t recall), which tool I have been using various versions of since the tool was first marketed in 1990 and can’t imagine working without despite its poor track record of longevity in more recent times–earlier this year I scoured the internet and bought enough of a supply to keep me in sanders for as long as I might need them–or so I thought. These sanders tend to fail in various inconvenient, if non-permanent ways, so it’s been my policy for years to always have a new spare on hand so as never to lose working time. I have a couple older ones on hand still awaiting inspection and repair, but it’s always easier to grab a new one.

So it was to my great dismay that earlier this fall, just a few days ago in fact, one of the new ones that I’d started using only in the spring began vibrating dramatically for no immediately apparent reason. I set it aside and opened a new sander, which, after all of a day’s use, began to vibrate in the same (or worse) alarming manner as I finished up the hatches. A bit of digging into the problem revealed that the screw securing the eccentric housing to the shaft had loosened on both of these tools, nearly right out of the box. I tightened the screws and both sanders seemed to work properly again. So the good news is I don’t have to retire just yet, as my sanders still work. The bad news is I can’t justify retiring yet because my sanders still work. But I’ll clearly have to check and tighten those screws right out of the box from now on, and probably regularly through normal use of the tool.)

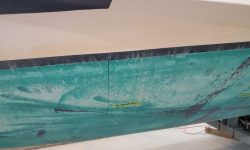

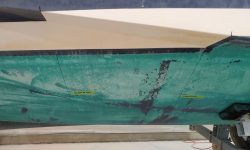

Continuing, I turned back to the starboard side of the hull and sanded the gelcoat, as before, with 60-80 grits on my 6″ orbital finishing sander that I like for broad surfaces requiring little in the way of material removal. I also worked the tool and grits over the new vent patches and the entire transom.

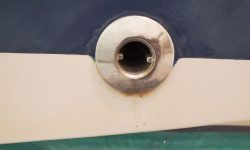

Later, I removed the winch and bow support assembly from the trailer to expose the middle portion of the stem, which would require a bit of sanding to bring it to the same state as the rest of the hull. I found the boat was a little bouncy on the trailer afterwards, so I chocked in a block beneath the bow to hold her steady.

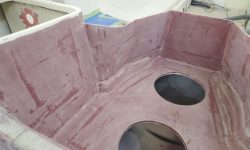

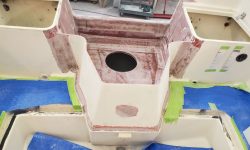

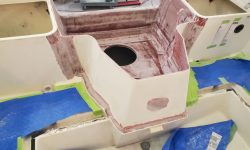

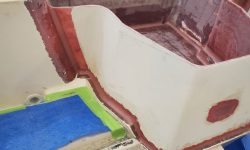

After some additional cleanup and preparations, I applied a coat of gray Bilgekote to the after portions of the bilge, beneath the new deck level. This would allow me to soon move forward with final installation of the outboard splashwell. The camera didn’t like the bright sunlight streaming in and hitting a corner of the bilge area, so a couple of these photos are out of focus.

Afterwards, I went around the hull and touched up with epoxy the few small scrapes, dings, and scratches that existed in the original gelcoat, and formed a couple fillets around the new trim pieces at the top edges of the transom.