Tuesday

It was a day to take care of various smaller details required as I edged towards the end of the deck repairs and surface preparations.

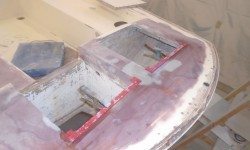

The original poop deck featured two raised areas aft of the hatch openings, which accepted the hinges from corresponding molded sections on the hatches themselves.

To recreate these on the rebuilt deck, I prepared two narrow strips of 1/8″ thick prefab fiberglass, the same dimensions as the original molded areas, and glued these to the deck with thickened epoxy. I wrapped two smaller (but oversized for now; I’d trim them later) pieces at the forward ends to replicate what was on the original deck. I clamped the pieces in their centers, but kept them essentially flat along their lengths, so they were a bit higher at the ends thanks to the curvature of the deck. This would correspond with the flat moldings on the hatches.

Later in the day, after the adhesive had had a chance to cure enough to continue working in the area, I applied the beginnings of fillets along the aft and outside edges of the new fiberglass, which would eventually create smooth transitions between the hinge mounts and the surrounding deck.

Inside the boat, I took care of a couple small repairs. One of the two sections of the supports for the mast step had a small crack in the fiberglass overlay towards one side; the support structure was otherwise sound. To reinforce this, I ground away paint as necessary and prepared the surfaces for new material. Afterwards, I installed a layer of biaxial roving over the area that had contained the crack.

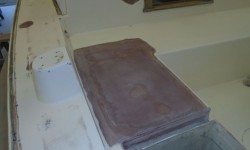

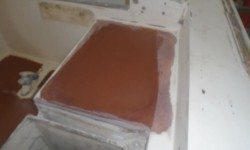

On the inside of the cockpit locker gutter assembly, which I discovered earlier had been partially pulled away from the cockpit molding, I ground away loose or damaged fiberglass and brought the surface down to raw laminate, removing paint and gelcoat as needed. Earlier steps during the recore had already resecured the gutter in place, but I needed to fiberglass it from the inside for real strength.

Once the substrate was prepared, I installed 6″ tabbing to secure the existing assembly to the surrounding deck moldings.

Total time billed on this job today: 4.5 hours

0600 Weather Report:

20°, clear. Forecast for the day: Sunny, 50