Wednesday

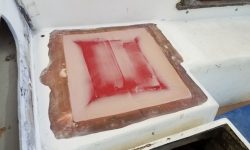

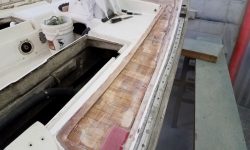

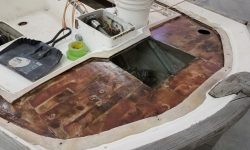

Next on my agenda was the old icebox hatch in the port forward corner of the cockpit. Earlier, I’d removed a molded collar and the center portion of the opening, leaving a raw hole through the deck that required patching and reinforcement.

Before getting into the rebuilding in earnest, I turned to the rudimentary electrical system located just below the hatch, consisting of a pair of battery boxes and some simple wiring that the owner had installed earlier in the year. Some of the cabling ran through wire mounts near the deck, on the old tabbing that had once connected to the ice hatch blank above.

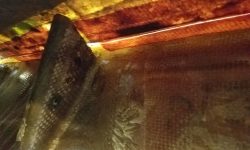

Additional work on the electrical system and battery storage area was part of the scope of this project, part of the upcoming list that I’d get to soon enough once I finished up most of the deck work and surface prep, but for now I wanted to clear the area to allow best access for the repairs above. Since the old half-attached tabbing on the bulkhead was in the way of my planned repair, and wasn’t worth salvage regardless, I removed the wires from the clamps in that area, freeing me to remove the tabbing itself with a chisel and just a little bit of elbow grease. I removed the batteries and some of their cabling, storing the batteries elsewhere for safekeeping; the battery platforms would require partial rebuilding, as well as expansion, according to my work list from the owner, so they needed to come out in any case: the upper area, at least, showed signs of significant damage to the plywood, with some crushing and breakage.

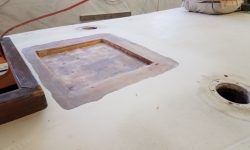

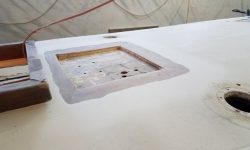

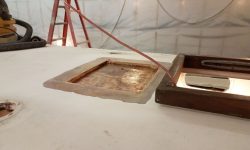

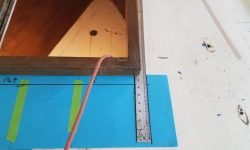

After some final surface prep to the underside of the laminate adjoining the icebox hole, as well as to the bulkhead where the old tabbing had been secured, I covered the opening from beneath with a prefabricated sheet of 1/8″ fiberglass, securing it with wedges and tape from beneath. This laminate would serve as a permanent mold for the new work, allowing me to laminate strongly over the top as well as tab securely from beneath to seal and strengthen the old opening.

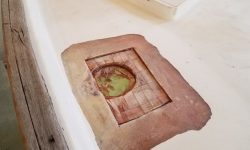

To secure this for now and also to allow a smooth transition between the fiberglass sheet and the surrounding deck areas, I filled the gaps around the edges with a strengthened and thickened epoxy mixture, forcing the adhesive into the gaps and creating a wide fillet on all sides. I left this to partially cure for the moment while I prepared a couple layers of fiberglass for the area and worked on a couple other related projects.

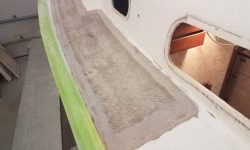

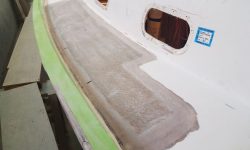

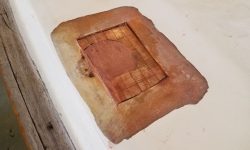

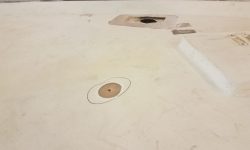

Meanwhile, I got back to work on the main mast step. My earlier laminates had nearly filled the void left by core removal, but since the inner skin was a bit inconsistent in its shape and depth, the forward side, particularly to starboard, was a bit lower than the port and after sides. So to start, I installed three additional layers of fiberglass over the lowest area, bringing this section nearly level with the surrounding deck and the other areas of the patch, then filled what remained smooth and level with epoxy thickened and reinforced with high-density filler and silica, just to even out the surface so I could laminate over the top.

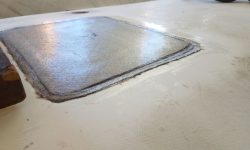

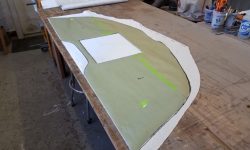

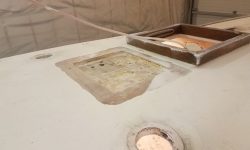

After a lunch break, the high-density epoxy filler on both patches had cured sufficiently to allow me to continue, starting with the icebox hatch. With two layers of newly-cut fiberglass, I laminated over the top of the new base, bringing the material out to the edges of the ground/prepared areas of the adjacent decks. These layers would form the basis for all that was to come. The patch was still low in the center, but I’d wait to install additional layers of fiberglass till the initial setup cured, mainly to ensure stability of the whole arrangement.

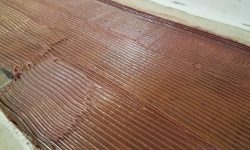

At the mast step, I installed two overlapping layers of fiberglass over the center of the patch and extending out over the adjacent sidedecks, completing the laminate work for this repair and tying the whole patch into the coachroof.

During the remainder of my reduced holiday-week-hours shop day, I prepared the chainplates to bring to a machine shop for reproduction, determining which ones were identical and could be used to copy related plates rather than bring the whole stack in. I also worked on other hardware assessment, busywork (yet necessary) that seemed to fit well with the lightweight schedule for the week; more on this to come in subsequent posts.

Total time billed on this job today: 4.75 hours

0600 Weather Observation: 0° , clear. Forecast for the day: Sunny, high about 10°