Phase 3: Finish

Work

|

Shop Home

Page

Shop

Planning

Phase 1: Site Prep and Foundation

Phase 2: Framing

Phase 3: Finish Work

Phase 4: Shop Setup |

Office

I

originally planned for the office to be a 15' square,

sort of "inserted" into the back corner of the building

(that is, extending five feet beyond the corner in both

directions). During framing of the interior walls,

however, we discovered that there was not enough space

for the bathroom to be properly functional. As a

result, we bumped the inner wall of the office into the

shop area by a few feet, allowing for a reasonable

bathroom, slightly shortening the wood shop, and

actually increasing the size of the office. For

more exterior views of the office wing, please visit

other portions of this site, where you will find them in

evidence. I

originally planned for the office to be a 15' square,

sort of "inserted" into the back corner of the building

(that is, extending five feet beyond the corner in both

directions). During framing of the interior walls,

however, we discovered that there was not enough space

for the bathroom to be properly functional. As a

result, we bumped the inner wall of the office into the

shop area by a few feet, allowing for a reasonable

bathroom, slightly shortening the wood shop, and

actually increasing the size of the office. For

more exterior views of the office wing, please visit

other portions of this site, where you will find them in

evidence. |

During the electrical phase of construction, I installed

outlet boxes and ran wiring, Internet, phone, and coax

cable into the office walls, to several locations that

would allow for versatility in the use of the space now

and in the future. Then, with the framing

complete, no further work occurred on the office wing

until after the insulation was installed in late

January. |

In early February, I prepared to install drywall on the

office walls and ceilings--the only space in the shop

(along with the bathroom) to receive this treatment.

Doing some rough calculations of the area, I determined

that I needed 23 sheets, though there would be

substantial waste from off cuts and window/door

openings. Grabbing a solitary fair weather day in

a week of rain and freezing drizzle, I managed to safely

deliver the drywall to the shop in preparation for a

hanging marathon on the upcoming weekend. A

friend, John Irving, had amazingly volunteered to help

with this task, and even seemed excited about it.

(So was I, truth be told...) |

In

a 10-hour day, we managed to hang all the rock on the

walls and ceiling. I had arrived early and

installed some insulation batts in the office ceiling

and the interior wall, since the insulation contractor

only insulated the exterior ceilings and walls; I wanted

the additional insulation for a sound barrier and to

help the office to maintain its own temperature, since

the other three heating zones in the shop would likely

remain at a lower temperature than the office. In

a 10-hour day, we managed to hang all the rock on the

walls and ceiling. I had arrived early and

installed some insulation batts in the office ceiling

and the interior wall, since the insulation contractor

only insulated the exterior ceilings and walls; I wanted

the additional insulation for a sound barrier and to

help the office to maintain its own temperature, since

the other three heating zones in the shop would likely

remain at a lower temperature than the office. |

Certainly the pros would have been

quicker at hanging the drywall, but we got the job done.

The job was complicated by numerous cutouts for ceiling

fixtures, outlet boxes, doors, and windows, but we

prevailed and, by the end of a long and tiring day, the

office was ready for the tape coat of joint compound

("mud"). I had hoped to be able to apply the tape

coat on the same day, but it was too late in the day and

clearly it would have to wait. |

The next day, I returned alone to install a few small

pieces of drywall and to apply the tape coat over the

seams. I completed this all in an easy 5 hour day,

and was pleased with the results. |

|

|

| Over the next several

days, I continued working on the office (and the

adjacent bathroom),

and applied two additional coats of mud to all the

seams. Each coat required 2-3 hours to apply,

followed by an overnights' drying time. With so

much to do, I commuted daily to ensure that I kept the

progress moving along. |

With the final coats of mud complete, I next turned to

an unenviable task: sanding. Maybe the pros

can lay this stuff down well enough to avoid any

sanding, but I cannot. So in a fun-filled 3 hour

marathon one morning, I hand sanded all the joints to

smooth them out and remove any minor ridges. While

none of the sanding was particularly heavy, every part

of the job did require sanding. When complete,

however, I was pleased with the results, and moved

forward with ceiling paint. I applied two coats of

flat white to both the bathroom and office ceilings. |

|

|

With the ceiling paint complete, I could install the

trim rings and bulbs for my recessed cans. This

went quickly, and after I wired up the switch I could

finally energize the circuit. I discovered to my

dismay that one of the 7 cans in the office did not

light--must be a loose wire nut or something. With

the drywall in place, there was no way to access the

wiring box without removing a portion of the drywall, an

irritating setback. Lesson learned: energize

and test the circuit for hidden fixtures before covering

with drywall. Much as I hated too, I supposed I'd

have to open up the ceiling in that area and repair the

wiring. Please see below

to read about the fix. |

|

|

In any event, it was time to continue

with the finishing work in the office. I made an

appointment for a carpet installer to measure and then

order the carpet for the room, and in the meantime I

wanted to wrap up the trim and painting, so that I

wouldn't have to worry about soiling the carpet. I

chose carpet because it is easy, inexpensive, quiet, and

comfortable for an office. More on the carpet

later in the process.After some

thought, I decided to press forward with painting the

walls first, and install the trim afterwards. I

chose this particular progression since the trim I

bought was pre-primed (making it easier to paint later),

and if I installed the trim after the walls were painted

it would be quicker to paint the walls; I'd still have

to cut in the trim paint later, but I would have had to

do that regardless. |

I began with a coat of some awful drywall primer.

It was terrible to work with, as it was cheap and

unsatisfying to apply, but it did the job and covered

the walls evenly. The primer would help the finish

coats spread more evenly, and avoid differences in

texture between the paper drywall surface and the mudded

areas. |

|

|

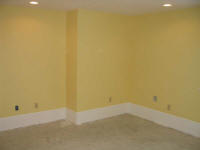

Once the primer was dry, in a couple hours, I rolled on

two coats of the final wall color. The actual name

of the paint is too embarrassing to post here, but I

chose a high quality Sherwin-Williams satin paint in a

pleasing yellow (with help from Heidi).

Note: all the pictures of the painted walls

also show the trim, since I only took pictures at that

juncture. |

|

|

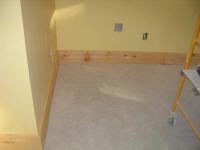

With

the paint dry, it was time to attack the trim. I

began with the baseboard trim, partly because it would

be the least likely to damage the fresh paint, and

partly because it was the most potentially challenging

portion of the trim installation, as well as the trim

most critical to have done before carpet. With a

6" concrete curb along the bottom edge of the wall--and

a uneven curb at that--it seemed the best approach would

be to simply cover it with a wide board, and then

install additional trim above as needed. I used

1x8 pine for the baseboard, which was tall enough to not

only cover the concrete completely, but also to allow me

to nail into the base plate of the wall. I used

construction adhesive to secure the pine to the concrete

where applicable; in some areas, I needed cleats at the

bottom edge, since the concrete was recessed from the

drywall in some areas, flush in others, and standing

proud in one corner. With

the paint dry, it was time to attack the trim. I

began with the baseboard trim, partly because it would

be the least likely to damage the fresh paint, and

partly because it was the most potentially challenging

portion of the trim installation, as well as the trim

most critical to have done before carpet. With a

6" concrete curb along the bottom edge of the wall--and

a uneven curb at that--it seemed the best approach would

be to simply cover it with a wide board, and then

install additional trim above as needed. I used

1x8 pine for the baseboard, which was tall enough to not

only cover the concrete completely, but also to allow me

to nail into the base plate of the wall. I used

construction adhesive to secure the pine to the concrete

where applicable; in some areas, I needed cleats at the

bottom edge, since the concrete was recessed from the

drywall in some areas, flush in others, and standing

proud in one corner. |

|

|

Over the top of the baseboard, I installed a pre-milled

base molding to finish off the edge and help hide the

uneven transition between the pine baseboard and the

walls. I nailed the base molding into the studs. |

|

|

The windows and doors required some pine extension jambs

to make up the wall thickness, and then I cased out

these openings using standard window and door casing,

with pine stools on the four windows. |

|

|

Between the office and the woodshop, I decided to

install an exterior steel door, as it would provide a

better seal against dust and noise. |

|

|

The

supply closet received some pine trim around the inside

of the opening, finished off with more door casing

around the edges. I planned to install a 48"

bi-fold door later in the process. The

supply closet received some pine trim around the inside

of the opening, finished off with more door casing

around the edges. I planned to install a 48"

bi-fold door later in the process. |

A week later, I painted the trim: 2 coats of

semi-gloss pure white on everything. |

|

|

With

the bulk of the office work complete, I took advantage

of a slow day to cut open the ceiling around the

non-functioning light fixture. I hated to open the

ceiling, but could see no other way around the problem,

as I was unwilling to live with the light in its current

condition. With

the bulk of the office work complete, I took advantage

of a slow day to cut open the ceiling around the

non-functioning light fixture. I hated to open the

ceiling, but could see no other way around the problem,

as I was unwilling to live with the light in its current

condition. |

I

rounded up a photo of the ceiling from before I

drywalled, so that I could determine the location of the

wiring box and the nearby framing. Then, I opened

the ceiling with a knife, gradually widening my opening

till I exposed the strapping on each side, and enough of

the ceiling was open for me to reach the fixture's

wiring box. Inside the box, I discovered that the

fixture's neutral wire had not been tightly secured in

the wire nut, so I replaced the nut and ensured the

connection, and also tested the light to make sure that

all was well. (It was.) I

rounded up a photo of the ceiling from before I

drywalled, so that I could determine the location of the

wiring box and the nearby framing. Then, I opened

the ceiling with a knife, gradually widening my opening

till I exposed the strapping on each side, and enough of

the ceiling was open for me to reach the fixture's

wiring box. Inside the box, I discovered that the

fixture's neutral wire had not been tightly secured in

the wire nut, so I replaced the nut and ensured the

connection, and also tested the light to make sure that

all was well. (It was.) |

Next,

I cut a patch of drywall for the opening, and screwed it

in place, installing additional pieces of strapping at

the short ends to support the seams there. Then, I

mudded and installed the paper seam tape. Next,

I cut a patch of drywall for the opening, and screwed it

in place, installing additional pieces of strapping at

the short ends to support the seams there. Then, I

mudded and installed the paper seam tape. |

Later

in the week, when I was back up at the shop, I applied

two more coats of joint compound to the repair. I

was fortunate to be able to not only apply two coats of

mud in one day, thanks to the relative thinness of the

coats over the repair, but also to be able to apply 2

coats of ceiling paint late in the same day, compressing

the final stages of the repair into a pleasantly short

time. Later

in the week, when I was back up at the shop, I applied

two more coats of joint compound to the repair. I

was fortunate to be able to not only apply two coats of

mud in one day, thanks to the relative thinness of the

coats over the repair, but also to be able to apply 2

coats of ceiling paint late in the same day, compressing

the final stages of the repair into a pleasantly short

time. |

With

the patch completed and covered with paint, it wasn't

even visible, unless one were looking for it (and even

then, it was tough). I was pleased with the

results, and glad to have the job behind me--an

irritation for which I had no one to blame but myself. With

the patch completed and covered with paint, it wasn't

even visible, unless one were looking for it (and even

then, it was tough). I was pleased with the

results, and glad to have the job behind me--an

irritation for which I had no one to blame but myself. |

|

|

I like carpet for offices--it's quiet and warm.

With Heidi's help, I chose a nice Berber in a blue/gray

tone, with multi-colored flecks. I ordered the

carpet from Lowes, and while the installation and carpet

was satisfactory, I found the whole process to be

unnecessarily complex and cumbersome.

The carpet installation virtually

completed the office work. All that remained was to

get some real furniture in there, and get to work!

For now, though, this folding banquet table would have

to serve as the nerve center for Lackey Sailing's world

headquarters. |

|

|

Some weeks later, I managed to complete

the work in the office. I built a large desk using

some basic Formica-covered tops (on MDF substrate),

which I installed using several filing cabinets as the

base. The three-sided desk filled most of the

corner of the office, and provided more than adequate

space for computers, printers, and other gear. I

looked forward to settling into my new, expansive work

space for good. I filled the other corners of the

office with a bookcase, drafting table, television, and

a chair. |

|

|

Click here to continue... |

This page was originally

posted on February 5, 2006

|

Updates |

2/12/06 |

| |

2/23/06 |

|

2/26/06 |

|

2/28/06 |

|

3/5/06 |

|

3/18/06 |

|

4/10/06 |

|

|