|

| |

| Barn

Home Page |

Click

here to see some of the specific framing details. |

|

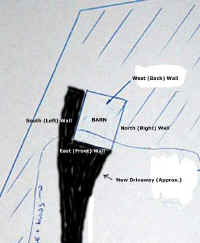

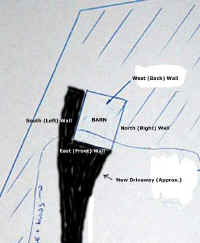

Getting Oriented

For your

convenience during this and subsequent discussions of the barn, It might

be useful for me to give you, dear reader, some directional references

concerning the barn. I will generally refer to the walls by the

direction they face, so knowing which is which could be helpful.  East

Wall: The front wall, featuring a large 18' wide door opening.

This wall obviously faces the driveway; it doesn't face directly east, but

it's the closest cardinal reference. East

Wall: The front wall, featuring a large 18' wide door opening.

This wall obviously faces the driveway; it doesn't face directly east, but

it's the closest cardinal reference.

South

Wall: Facing the front of the building from the driveway, this

is the lefthand wall. It's the wall that runs along the gravel boat

storage pad next to the slab. For maximum natural light, I plan on

installing a series of windows high up in this wall. There is also a

6' wide by 10' high utility door planned near the back side of this wall

for easy access to and from the pad. North

Wall: Facing the front of the building from the driveway, this

is the right-hand wall. This is a basic, blank wall, broken up only

by a 3' wide entry door near the front (east) corner. West

Wall: The back wall. The design calls for a row of five

windows, located a little over 3' above the floor and centered in the

wall. This wall backs up closely to the trees behind the site. |

Monday, August 18, 2003

Framing Day 1 It

was a leisurely start on the site this day for Bob and Lee. They

rolled in about 0845 followed shortly by a flatbed lumber

delivery truck piled high with 2x6s, 2x10s, and a large stack of T-111

plywood siding. I went out and discussed with Bob the final details

on the rough openings for some framed windows and doors. The lumber

truck tipped its load onto the driveway in front of the barn and took off. It

was a leisurely start on the site this day for Bob and Lee. They

rolled in about 0845 followed shortly by a flatbed lumber

delivery truck piled high with 2x6s, 2x10s, and a large stack of T-111

plywood siding. I went out and discussed with Bob the final details

on the rough openings for some framed windows and doors. The lumber

truck tipped its load onto the driveway in front of the barn and took off.

|

|

I

was gone most of the day, after Bob and I talked over a little more of the

nitty-gritty, but when I got home in the afternoon there were signs of

progress--though the crew had already gone home. I

was gone most of the day, after Bob and I talked over a little more of the

nitty-gritty, but when I got home in the afternoon there were signs of

progress--though the crew had already gone home.

No walls were actually

completed, but it looked like a substantial amount of pre-cutting had

occurred, and the south wall, which is the most complex of the four walls

since it contains window and door openings, was all laid loosely out with

all parts cut to size, but not nailed together. I made a few quick

measurements of the openings and such to ensure that all was as

designed--no mistakes were evident. When I had my garage on the

house built in 1996, the crew screwed up royally on the first day, framing

all the walls over a foot too short. Duh. So I was careful to

ensure that the framing--and other parts of the barn job--went according

to plan from the getgo. |

|

|

|

Tuesday, August 19, 2003

Framing Day 2

Another

hot, beautiful, clear day--perfect for framing. Bob and Lee got

right to work, beginning where the left off the day before: nailing

up the first (south) wall. I was away most of the day, but when I

returned in the midafternoon both side (long) walls were complete, all

nailed up and lying on the slab. The south wall contains a series of

openings for windows, as designed, plus a large side door opening near the

back; the north wall is unadorned and very simple, except for a normal man

(ingress) door near the front corner, nearest the house. The walls

are framed with 2x6 lumber over 2x6 pressure-treated bottom plates, with

slim metal angle bracing at the end corners. With roof trusses

not scheduled for delivery here until the 28th, I don't think Bob felt any

particular pressure to (ahem) bang the framing out as quickly as possible,

so they aren't tending to work particularly long days. Bob and I

were both hopeful that the trusses might get delivered earlier and keep

things moving along. Another

hot, beautiful, clear day--perfect for framing. Bob and Lee got

right to work, beginning where the left off the day before: nailing

up the first (south) wall. I was away most of the day, but when I

returned in the midafternoon both side (long) walls were complete, all

nailed up and lying on the slab. The south wall contains a series of

openings for windows, as designed, plus a large side door opening near the

back; the north wall is unadorned and very simple, except for a normal man

(ingress) door near the front corner, nearest the house. The walls

are framed with 2x6 lumber over 2x6 pressure-treated bottom plates, with

slim metal angle bracing at the end corners. With roof trusses

not scheduled for delivery here until the 28th, I don't think Bob felt any

particular pressure to (ahem) bang the framing out as quickly as possible,

so they aren't tending to work particularly long days. Bob and I

were both hopeful that the trusses might get delivered earlier and keep

things moving along.

|

|

|

|

For my own future reference

and interest--and anyone else's, of course--I decided to catalog many of

the specific framing details as they occur, creating a photographic

instruction manual, of sorts, from which to draw information at some later

date. Click

here to see some of the specific framing details. |

Thursday, August 21, 2003

Framing Day 3

After a day away from the site so he could

tend to some personal business, Bob was back bright and early at about

0630. The forecast for the day was for some pretty intense heat, so

obviously he figured it would be best to get started early in the day

before the heat was too bad (it gets very hot out on the slab, as it is

directly in the sun during all of the morning and through the hottest part

of the afternoon before finally beginning to get shaded at about 1500).  Bob

and Lee set right to work tacking on the sheathing onto the two wall

sections already built. I'm using T-111 plywood sheathing, which

doubles as siding because of its grooved external finish. It's a

budget choice--I'd enjoy having cedar clapboards and shingles--but it gets

the job done quickly and efficiently, and doesn't look too bad. I

vastly prefer it to vinyl siding, which was the other budget choice.

When painted up and trimmed properly, the plywood looks decent. One

benefit to T-111 is that is forms a good base should I choose, at some

later date, to install shingles or claps over the top, should desire and

current budget dictate such a change. Bob

and Lee set right to work tacking on the sheathing onto the two wall

sections already built. I'm using T-111 plywood sheathing, which

doubles as siding because of its grooved external finish. It's a

budget choice--I'd enjoy having cedar clapboards and shingles--but it gets

the job done quickly and efficiently, and doesn't look too bad. I

vastly prefer it to vinyl siding, which was the other budget choice.

When painted up and trimmed properly, the plywood looks decent. One

benefit to T-111 is that is forms a good base should I choose, at some

later date, to install shingles or claps over the top, should desire and

current budget dictate such a change.

|

|

The got the sheathing installed on both sidewalls, and then began laying

out the back wall on top. By about 1130, I guess it was too hot,

because they knocked off. When I went out later to check out the new

work, I noticed immediately that they had begun to frame the windows shown

on the back of the barn in the wrong place; they had begun to frame them

as clerestory windows (like the ones on the south wall) instead of down

lower in the wall as shown on the plan. Fortunately, the windows

were not completely framed in--only the bottom edges of all the studs were

nailed, and no headers or jambs had been installed yet.

The got the sheathing installed on both sidewalls, and then began laying

out the back wall on top. By about 1130, I guess it was too hot,

because they knocked off. When I went out later to check out the new

work, I noticed immediately that they had begun to frame the windows shown

on the back of the barn in the wrong place; they had begun to frame them

as clerestory windows (like the ones on the south wall) instead of down

lower in the wall as shown on the plan. Fortunately, the windows

were not completely framed in--only the bottom edges of all the studs were

nailed, and no headers or jambs had been installed yet.

|

|

This mistake got me thinking long and hard about whether I wanted the

windows moved down, as planned, or whether it made sense to leave them up

high as framed. Both options made sense, but in the end I thought the lower

windows might be nice to allow some views outside when working at floor

level in the barn--always an important consideration. The windows'

designed location is such that their sills will be several inches above a

bench I planned to build along the back wall.

This mistake got me thinking long and hard about whether I wanted the

windows moved down, as planned, or whether it made sense to leave them up

high as framed. Both options made sense, but in the end I thought the lower

windows might be nice to allow some views outside when working at floor

level in the barn--always an important consideration. The windows'

designed location is such that their sills will be several inches above a

bench I planned to build along the back wall.

|

|

Friday, August 22, 2003

Framing Day 4

I had to leave early in the

morning, so I didn't have a chance to chat with Bob about the window

framing. So I left a note on his trailer to let him know, and when I

returned later in the day he had reframed all the openings as

needed. As it turned out, it was just as well, as Bob related to me

later: yesterday, he had framed the window openings with the wrong

measurements to begin with, reversing the width and height measurements,

so the windows had to be reframed anyway. He explained that this

unknown quantity, in addition to the general heat of the day before, was

why they had knocked off early, and had even gone to the store to measure

the windows physically to ensure which way was which.

The

newly-framed openings and back wall looked great, and by the end of the

day they also had the front wall framed up; this was a relatively easy

wall, as it features a large door opening (18' W by full height, minus the

10" header at the top). They left the front and back walls

unsheathed, saying they preferred to apply the sheathing once the walls

were standing because it made framing the gables easier, etc.

Whatever they like is fine with me! The

newly-framed openings and back wall looked great, and by the end of the

day they also had the front wall framed up; this was a relatively easy

wall, as it features a large door opening (18' W by full height, minus the

10" header at the top). They left the front and back walls

unsheathed, saying they preferred to apply the sheathing once the walls

were standing because it made framing the gables easier, etc.

Whatever they like is fine with me!

Click

here to see a series of detailed photos of the framing. |

|

With

that, the basic framing was done, and work was over until the roof trusses

arrived. The trusses were scheduled for delivery in just under a

week, the next Thursday, August 28. The walls and trusses will be

raised in one day with a crane on site; the crane was scheduled for the

following Tuesday, September 2. With

that, the basic framing was done, and work was over until the roof trusses

arrived. The trusses were scheduled for delivery in just under a

week, the next Thursday, August 28. The walls and trusses will be

raised in one day with a crane on site; the crane was scheduled for the

following Tuesday, September 2.

|

Continue>

|

|

|