January 4, 2025

PT11-48

Saturday

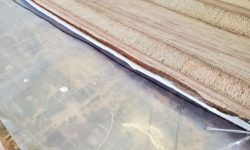

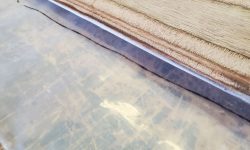

The rudder and daggerboard required some preparation before I could install the fiberglass on the second side. To begin, I used a knife trimmed the excess cloth from the first side.

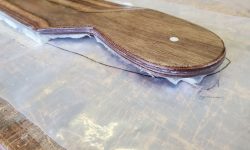

The leading edge required some sanding and shaping to finalize the profile and bevel and slightly round the epoxy bead I’d installed from the first side. This wasn’t difficult and didn’t take long, but one could see how it might easily be done incorrectly, as the job required a certain sense of what the shape should be and how to create it. I masked the plywood to help gauge where the sanding was occurring, and used a small sanding block to bevel and shape the epoxy leading edge, sweetening it by hand thereafter. Around the remainder of both foils, I lightly sanded flush the remnants after I’d cut away the excess cloth, and sanded the top edge of the cloth where it wrapped onto the plywood edges at the 18mm thick top sections of each foil.

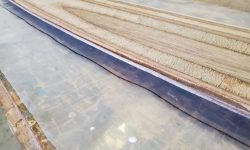

I sheathed the second side of the foils the same way as the first, with one layer of 4 oz. cloth and, on the daggerboard, a second layer at the top, which extended an inch or two down onto the hydrofoil. The cloth wrapped over the edges of the full-thickness portion of each foil, extending well past the seam from the first side. As before, I let the excess cloth on the leading edge side drape well past the curve to help the fiberglass cling to the newly-shaped area as required.

In other works, I trimmed and lightly sanded the sheathing I’d installed over the outboard modification at the transom, and then fill-coated the area to fill the weave of the cloth, essentially finishing up the work on this area.

The bulk of the small parts now had enough varnish for installation, but the top, visible side of the aft seat still required a few sprayed coats, which I finished up during the day.

Later in the day, when the fiberglass on the foils had had about 5 hours’ cure time, I returned to apply the epoxy fill coat to both parts, rolling on a thick coat of epoxy to fill the weave of the cloth and prepare the second side for eventual sanding and final fairing.

Total time billed on this job today: 2.5 hours