December 18, 2024

PT11-37

Wednesday

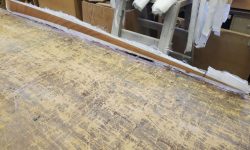

Everything was ready, so I got right to work wetting out the hull sheathing fabric. The process was unremarkable and posed no issues. At the stem, I wrapped the cloth around and over so that it overlapped roughly an inch on the opposite side; the second side did the same, doubling the amount of material on the stem and the first foot or so of the bottom panel. Then, to top things off, I installed two tapered layers of 4 oz. cloth that I’d previously cut; these extended from the knuckle to the top of the stem and overlapped one another, as well as the seams of the overlapping main layers beneath. I left excess cloth to overhang the gunwales and at the amidships bulkheads.

At the transom, once I’d wet out the cloth I trimmed the excess length to leave about 1/2″ of cloth, which I then wet out and wrapped over the rounded transom corners. On both hull halves, the cloth wrapped over and onto the bottom panel by an inch or so (more at the forward end of the bow); I’d install the sheathing on the bottom in another round of work next time.

While waiting for the fiberglass to cure enough for the fill coat later in the day, I prepared the fiberglass for the outboard edges of the gunwales, and fiberglassed both sides of the skeg after sanding the glue-up remnants from installing the fiberglass base cap.

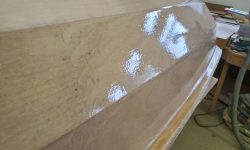

In the afternoon, the resin had gelled enough that I could install the fill coat on the hull. For this fill coat, on advice of the book I added 50% by volume of 410 microlight filler to the resin (I started with an 8 oz. batch of resin, and added 4 oz. of the filler, firmly packed). I used a 1/4″ mohair roller to apply the epoxy to the hull, spreading it as evenly as possible, then finished off the work by rolling again with a foam roller, which helped smooth out the texture. As the material leveled, it achieved a glossy texture. I hoped that this application would be heavy enough to completely fill the weave of the cloth, but only time would tell. Other than adding thickness to the coat, the filler had the main advantage of helping the epoxy cling to the hull with far less inclination to run or sag, as it might tend to do in an unthickened state, and I was impressed with how well this seemed to work. Another advantage was that the filler would make the coating much easier to sand flat and smooth.

Total time billed on this job today: 5.5 hours