December 12, 2024

PT11-33

Thursday

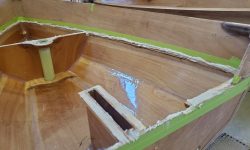

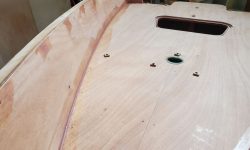

Now that the forward half of the boat was gloss-coated on the inside, it was time to permanently install the foredeck. I applied unthickened epoxy where needed to prepare bare wood or plywood edge grain, then installed beads of thickened epoxy adhesive on all bearing surfaces: mast step and daggerboard trunk; the hull edges along the foredeck; the edges of the foredeck itself; and the aft bulkhead and cleats.

I set the foredeck in place and secured it with the 11 screws and little pads. I had good epoxy squeezeout everywhere, as there should have been.

Next, I cleaned up all the excess epoxy and removed masking tape as needed.

Belowdecks, there was also good epoxy squeezeout everywhere, visible only through the eye of the camera.

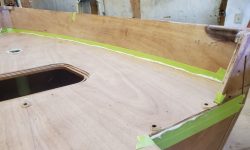

With the foredeck installed, now I could move on and install the breasthook. I had to modify the aft part of the edges to get the pre-machined part to fit closely enough into the curve of the stem and gunwale (it didn’t need to be a perfect fit, just close). To hold it at the proper level, I hot-glued some small alignment blocks to the top, which blocks rested on the edge of the hull planking on each side, and glued the breasthook in with the usual routine of epoxy priming and thickened epoxy. The gunwales continued their curve above the height of the forward end of the breasthook, but this area would get trimmed down once the epoxy cured.

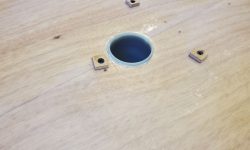

Despite keeping the photos above all together for continuity of the project, in reality I did the breastook fitting first, then, before installation, I installed epoxy fillets along the intersection of foredeck and hull. With leftover epoxy, I filled the holes at the gunwale leftover from its original installation; I hand-milled small countersinks at each hole location before filling it with the thickened epoxy.

While I was finishing up this work, the power went out, always my favorite thing. We’d survived a doomsayer windstorm overnight without issue, but now, with bright sunny skies and only moderate wind gusts of perhaps 25, we lost it. But the shop was bright, and I had no immediate need for power tools, so I continued working on various preparations to their natural end. The power came back on around 1400.

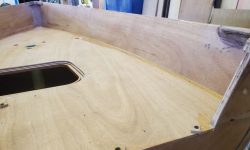

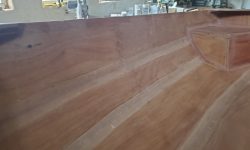

I turned my attentions to the stern half, which required some minor preparations before tomorrow’s planned work. As with the forward half, I filled all the gunwale installation holes, and also touched up the various alignment slots in the transom and stern quarters. I should note that my filling/fairing technique has always been to sneak up on the final result with multiple levels of fairing application as needed, never to overfill and sand down. This is one place I have consistently differed with the instructions in the build manual for this boat.

At the same time, I used some of the epoxy to fill a second time the screw holes at the gunwale reinforcements I’d installed earlier. The top transom edge required rounding over, which I accomplished with a sanding block.

The next major step in the process was going to be to install fiberglass reinforcement on many of the exposed edges, including the tops of the gunwales, the exposed bulkhead edges, breasthook, and transom inwale. To this end, I cut various pieces of fiberglass and peel ply to size as directed in the manual. There’d be a bit more sanding and milling prep to certain areas before I could do the glasswork, and with curing epoxy everywhere that would be the first task next time.

To get a bit ahead of the future game, I did one minor step required to the skeg, which was the last major component to finish off the hull itself. As described in the manual, I tapered the aft edge of the plywood skeg on each side, then built a little dam of three layers of masking tape on both sides and injected some thickened epoxy material into the gap. Once cured, this would give the trailing edge of the skeg the hardness of epoxy–exactly how will make itself more clear in subsequent steps. The skeg would be sheathed in fiberglass before installation.

Total time billed on this job today: 6.25 hours