November 15, 2024

PT11-16

Friday

I continued work on the foredeck and installed the cleats I’d prepared last time, following the usual steps of pre-wetting the bonding surfaces with epoxy, then installing in a thickened epoxy mixture. I secured the cleats with the nailing pads and clamps on the after part of the seat tongue, and cleaned up all the excess epoxy.

Next, I cut and installed 2″ fiberglass tape over the centerline seams (just the aftermost 6″ of the aft part of the seam). I also installed a strip of fiberglass on the outside edge of the foredeck hatch, a process designed to provide a more durable hatch edge. Late in the day, I applied a fill coat of epoxy on this narrow edge as well.

I epoxied the second side of the daggerboard trunk in place, ensuring it was aligned with the first side at both ends.

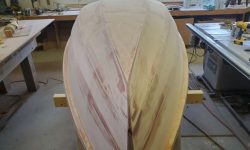

Next, I sanded the hull to clean up the epoxy-filled chines all over. Some minor fine-tuning remained, but overall the hull and chines were looking good.

I shaped the stem to form a smooth curve following that of the gunwale at the top edge, and tapering to a narrow profile at the cutwater.

With the hull back upright again, I removed the transom formwork, as the transom shape was now well-supported by the hull, inwales, and fillets. I lightly sanded the transom fillets, then marked and cut the aft bulkhead to remove the center portion after removing the remaining stitching wires. I also removed the amidships bulkhead, which would require a long series of steps to prepare it and its forward counterpart for final installation.

Now I installed epoxy fillets on both sides of the mast step bulkhead, and the after sides of the aft bulkheads; the forward sides would receive their fillets later, once the rest of the seat/tank components were in place. I also touched up a couple places on the transom fillets, and fillet the remaining seams between the transom face, hull panels, and inwales.

I inverted the hull once more, then installed a small epoxy fillet where the hull met the underside of the gunwales along the entire lengths, using some of the excess epoxy to begin to fill the bulkhead tongue slots (aft and mast step bulkheads) and the hull chines where the amidships bulkhead had been. I finished things off with a rolled coat of unthickened resin on the edge grain of the gunwales. These steps with the gunwales were preparatory as we slowly neared the task of glassing the hull.

Total time billed on this job today: 7.5 hours