Tuesday

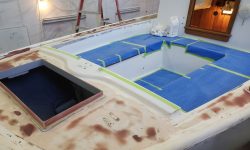

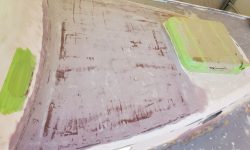

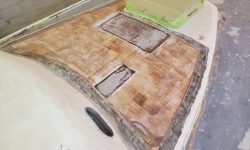

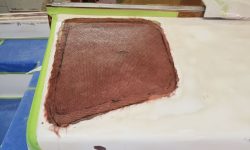

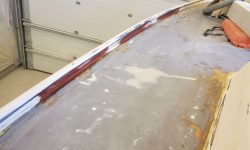

I started by removing the weights and paraphernalia from the new core installation. Later, I washed and lightly sanded the area to scuff the surface, remove any hard edges, and, in a couple areas, pare down the core a bit where it was a little high, mainly around the fiberglass bulge on the starboard side. (It seems somehow I forgot to take any photos after the sanding, unfortunately.)

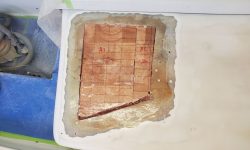

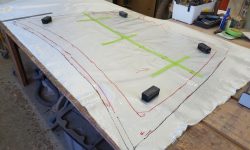

Before getting into any dirty work, I made basic patterns of the mast step and bulge areas, which I planned to fill with solid fiberglass, and also of the smaller recore area on the upper coachroof, so I’d have these available for cutting the smaller pieces. I’d hoped to start building these up now, but, still awaiting my new roll of fiberglass, I found I didn’t have scraps large enough for these areas (other than the smallest one), so I postponed that for now.

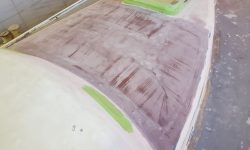

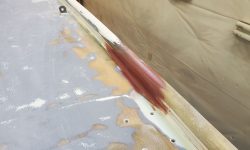

On the underside of the repair, I sanded a little more around the edges and with a finish sander to fine-tune the first round of sanding from the day before, and removed the masking so I could clean up the edges.

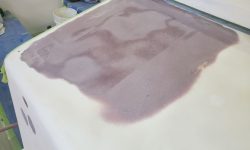

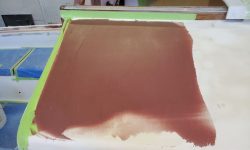

After cleaning up above and belowdecks, I used more thickened epoxy to fill the kerfs in the core, and to fill around the edges as needed.

On the overhead, I spot-filled as needed to take care of the various minor low spots left behind, and clean up some of the edges. This would be the final round of filler on the overhead.

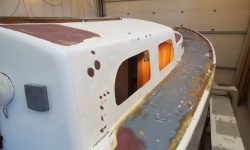

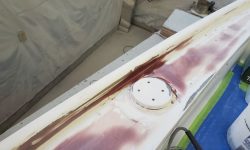

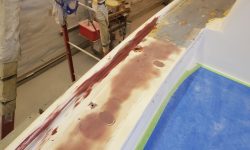

I went round the decks, focusing mainly on the toerail, doing any final hand-sanding required and marking areas that would require some epoxy work. I also scraped and sanded away final bits of the old paint around the companionway and forward hatches. After cleaning up the decks, I applied epoxy fairing compound as necessary, mainly at the base of the toerails to clean up the fillets there, but also in a few other areas where needed.

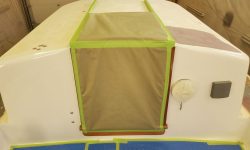

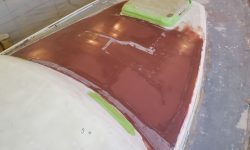

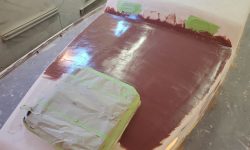

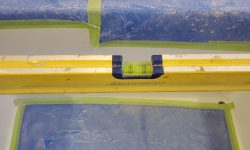

With the arrival of my fiberglass late in the day, and the coachroof area cured sufficiently for this purpose, I went ahead and made a plastic pattern of the whole area, marking both the overall edges of the repair (for the largest piece) and the inner section along the cut lines. Before the end of the day, I laid out and cut the largest piece required for the new top skin, which I’d test fit on the morrow when the epoxy was fully cured and then use it to create the slightly smaller second layer, before moving onto the remaining fiberglass patterns.

Total time billed on this job today: 6.5 hours

0600 Weather Observation: 27°, partly cloudy. Forecast for the day: Sunny, windy, temperature dropping.