< Back to Danusia

Wednesday

With new saw blades on hand, I felt I needed to conquer the windlass before Christmas break, as I hated to leave things unresolved. I wanted that windlass out. At this point, I almost didn’t care how it got out–as long as it did. I couldn’t stand seeing it there, sneering at me and pretending it was just so superior.

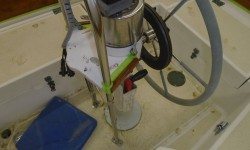

First, I tried–in a laughingly brief way–to use a length of pipe to bang on the steel part of the shaft housing surrounding the bronze turning shaft. This was so utterly ineffective (exacerbated by that cove shape the housing had ended up), and I quickly turned to the saw, fitting it beneath the bronze deck plate where I’d already reamed out the sealant earlier. This was really the only practical access to cut the windlass into pieces, as space belowdecks was simply too tight and basically inaccessible where the shaft was. If this didn’t work from on deck, I wasn’t sure what I’d do.

I found it worked for me to stand on the staging next to the boat and hold the saw along the aft side of the shaft–this gave me the best leverage. It took about 30 minutes and two saw blades to make it through. At first it was impossible to tell whether I was making progress or not, as I couldn’t really see into the narrow slot, and certainly the cutting progress was not something one could measure by eye or feel. I think the first blade must have dulled quickly on old sealant or wood, as once I’d changed to the new blade after a time the progress seemed quicker. In any event, eventually I completed the cut, freeing the deck plate. Success! Or so I thought.

I’d kind of expected that once I’d made the cut, I’d hear the windlass drop out below. Planning ahead for this, I’d lined the chainlocker with an old cushion and towel to soften the blow, but the shaft and housing held tightly in the wooden deck riser with no sign of movement whatever. After checking things out below, I returned to the foredeck and, using a small hand-held sledge, I pounded the top of the shaft, both with my length of pipe (limited or no success at first), and then without, It took surprisingly brutal effort to budge the thing at all, and at first all I heard was more chunks of thick, flaky rust crumbling off the windlass, but after a number of severe hits I saw progress, as the shaft started plunging through the wood. Finally, at length, the windlass gearbox and motor came free and fell the short distance onto the pillows.

Even though I’d removed–by corrosive attrition and as a byproduct only–probably 10 pounds of rust (a full 5 quart bucketful) from the windlass housing during the removal process, what remained of the windlass and motor was extremely heavy. I was so glad to get it out of there and down to the bench with all its component pieces (except the capstan drum, which I forgot to include in my still life photos below), What a piece of junk this thing turned out to be. What all this plain steel was doing in a windlass was beyond me. A real shame, as I know the working components were all bronze and stoutly built. To shroud such fine mechanicals in this steel case was obviously a poor choice.

With the windlass finally out of the way, I cleaned up the deck and chainlocker as needed, including removing the semi-circular deck riser adjacent to the bowsprit, as the removal had damaged this easily-replaceable piece. The good news in all of this was that the deck in this area was core-free, just a solid 1/2″ or so laminate. Briefly inspecting things from beneath, it seemed this might have been a planned omission at the time of construction specifically to allow for a windlass installation on this side. But at least the large through-deck hole had not allowed any damage to the decks, which couldn’t be said for the windlass itself.

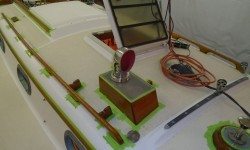

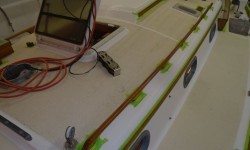

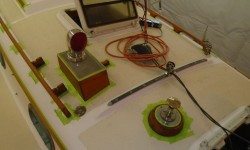

During some work in the port cockpit locker a little earlier, I’d noticed the other ends of the large windlass cables hanging out of the wire chase on that side. Besides being too short to reach a battery, the cable ends weren’t looking too great, and one of the cables had a cut in the insulation that would obviate the last foot or so of that cable. So whatever happened from here in terms of windlass replacement, there’d unfortunately be more wiring work to complete.

Total time billed on this job today: 1.5 hours

0600 Weather Report:

Fog, clouds, 35°. Forecast for the day: clouds, rain coming overnight, high in the low 40s