< Back to Acadia

Friday

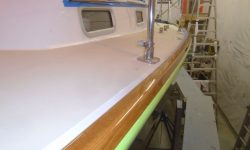

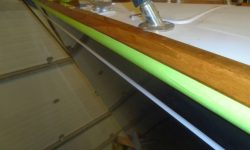

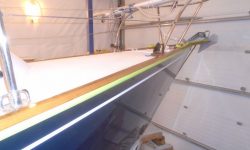

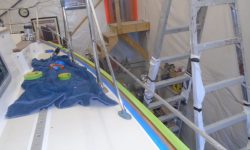

The port coaming looked good now, so I removed the masking tape. This completed the work on deck.

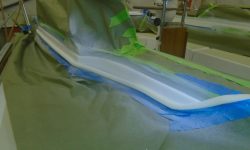

I sanded the patches on the rudder and keel as needed, smoothing them and fairing into the adjacent surfaces.

The repairs were small, and my initial coat of fairing compound took care of both areas, so after cleaning up I coated the newly faired repairs with unthickened epoxy.

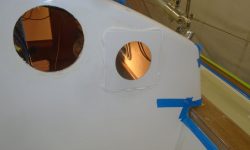

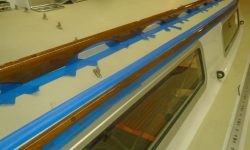

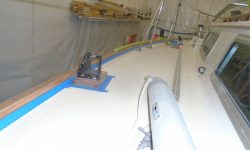

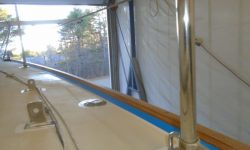

Now that the epoxy-filled bolt holes had cured overnight, I continued with the installation of the two new winches on the cabin top. The original winches had been installed through round holes, strategically located at each bolt location, in the fiberglass cabin liner, but with a different bolt pattern and a desire to use larger washers, I preferred to open up a section of the liner completely in order to access the underside of the deck. Plus, the bolt holes for the new winches were close to the outline of the teak cover panels that I’d removed from these areas, so opening larger square holes in the liner would allow the bolts to remain hidden. I marked the liner inside of the outline of the cover panel, and cut out the area within to gain better access. At the edges of each opening nearest the companionway, there was some filler/adhesive material between the liner and the deck, probably the material used to secure the liner during construction, and I had to chip some of this away to allow room for the new bolts and washers. The tape in the first photos is left over from filling the old bolt holes the day before.

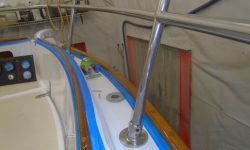

After masking around the winch bases and marking the holes, I drilled and tapped for 1/4″ machine screws, and installed the winches in a bed of sealant in the usual way, securing from beneath with fender washers and nuts. Reassembling the winch drums, I temporarily installed the plastic screw caps on top.

Later, in an impressively quick turnaround, the replacement (proper) stainless steel winch caps arrived from Lewmar just a day after my request, and I completed the installation by installing them.

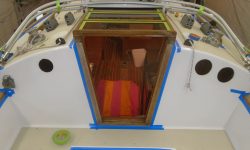

The main cabin finishes were mainly original, and the old finish was showing its age in many areas, with varnish beginning to fail and a generally tired appearance. The owner asked me to refinish the trim and the main bulkheads with varnish, and to prepare and paint the lower settees, nav station, and galley cabinets with white paint to spruce up the appearance.

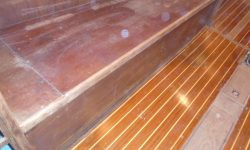

The main portion of the cabin sole had been replaced (or overlaid) with new teak and holly plywood at some point, but the small section of sole in the nav station footwell was still original. I happened to have a piece of cabin sole plywood on hand, leftover from something else, and it would work well to finish off this final area.

To prepare the cabin for the work ahead, I began by removing all the contents of the drawers, lockers, and overhead shelves, packing everything into a series of paper bags that I stored on the foredeck out of the way.

Now I went through the cabin and removed all the drawers, hinged door fronts, backrests, and the unfinished teak molding at the edge of the cabin sole, along with anything else that was removable and might impede the refinishing work. I restrung my work lighting so the cords were above deck and the lamps attached to places out of the way and where I wouldn’t be refinishing. I brought all the drawers and doors, all of which would be finished bright, down to the bench for later attention.

Total time billed on this job today: 5.75 hours

0600 Weather Observation:

40°, clear. Forecast for the day: Sunny, high 50s