Monday

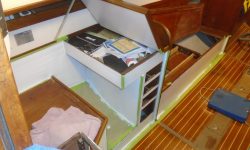

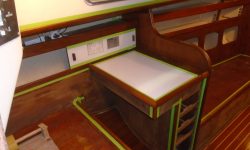

Over the weekend, I decided that a few of the painted interior panels required a third coat of paint, as I wasn’t happy with some thin/dark spots at the upper edges, where coverage hadn’t been as good as I’d hoped. So after basic preparations, I applied a third coat of paint to the panel outboard of the nav station on the port side, the small section above the aft galley countertop, and portions of the galley and engine compartment.

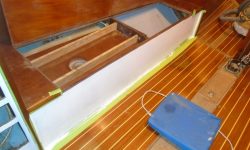

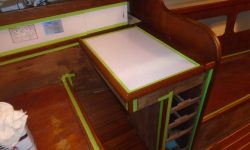

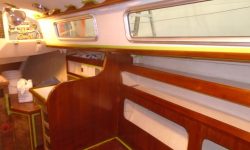

Now, with the paint work complete, I removed all the masking tape from the cabin. Final installation of the base trim and various doors and drawers would bring the whole thing together soon.

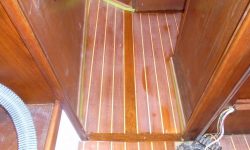

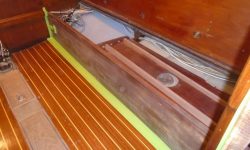

The cabin sole had looked pretty good at the beginning of the project, but as work progressed in adjacent areas, it looked more and more downtrodden, and some time earlier I’d decided that I’d fo a quick refresher coat of varnish on the whole thing to spruce it up. The existing finish was fair, but rather rough, and there were bare teak trim thresholds and center trim and hatch pieces that had never been finished, along with a single oddball plank in the passageway. There was some water damage on the port side, which had stained the veneer and lifted some of the old finish.

To prepare, I sanded the existing finish with 120 grit, concentrating as needed on the damaged area to port and cleaning up the bare wood as well. Afterwards, I vacuumed and solvent-washed, and masked off some areas in the passageway to prepare for new varnish.

Preparations complete, I applied a thin sealer coat of varnish to the bare wood sections only.

The thin sealer coat cured enough during the day so that I could go back later and apply a fresh coat of varnish over the entire sole, including the bare areas and center hatches once more.

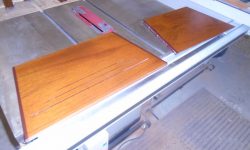

A couple of drawer fronts had been uncooperative in properly accepting my second coat of satin varnish earlier, so I sanded these and applied another coat, and also a final coat to the main side of the bookshelf; I’d varnished the inside of this unit over the weekend.

Total time billed on this job today: 5.25 hours

0600 Weather Observation:

20°, snow (2-3″ so far). Forecast for the day: snow (6″ total ), ending mid-day