Friday

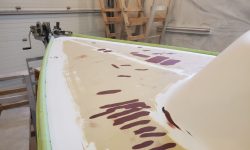

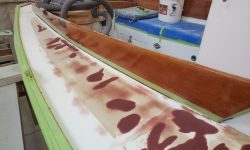

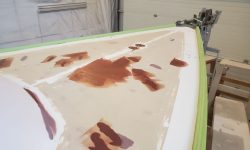

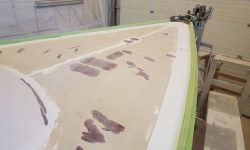

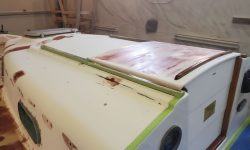

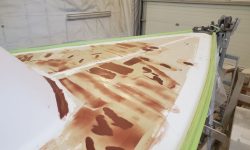

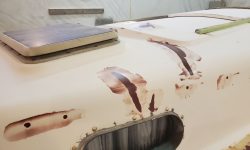

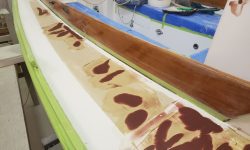

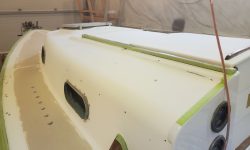

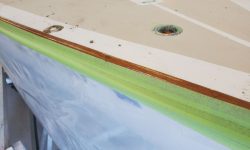

During the morning, I sanded all the deck areas once more, all finish sanding by machine and hand with 120 grit, to bring the decks to their pre-primer state of readiness.

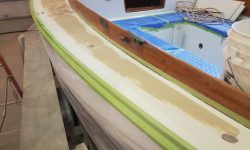

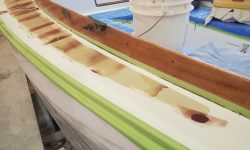

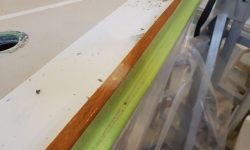

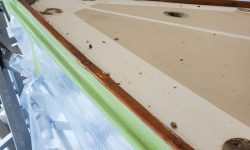

After a fairly thorough cleaning of boat and shop, now that the heaviest sanding was complete, I relocated the four stanchion bases as requested by the owner. The bases had originally been installed flush against the inside of the toerail, which didn’t leave sufficient room for proper drainage or for adequate maintenance of the wood. Belowdecks, I checked each of the four locations to determine how far I could move the bases inboard; the way the bases landed over the hull/deck flange, and the amount of room available inside the molded liner, affected the position of all four bases, and using the least-good situation as my baseline, I determined I could move the bases in about 1/4″, a reasonable compromise between the hoped-for effects and the various practical considerations forced by the boat’s construction.

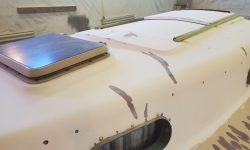

For the forward pair of bases, this was the only position adjustment required, so using a pencil as an easy guide (it was 1/4″ in diameter), I repositioned the bases and drilled small pilot holes through each mounting hole. These holes did not penetrate all the way through the deck, and would serve to mark the bases’ locations through the two primer applications so that I could easily locate the bases later.

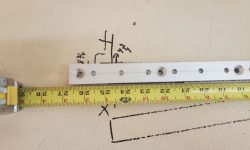

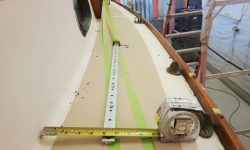

For the after pair of bases, the owner also requested that I move them forward, to help make up for a slightly overlong lifeline gate section that had maxed out its adjustment. From examining the turnbuckles at the fixed, forward end of the lifelines, I determined that I could safely move the bases forward 1/2″, so after marking the original position with tape, I made the forward adjustment and, along with the new 1/4″ space at the toerails, marked and drilled the pilot holes for the two after bases in their new positions.

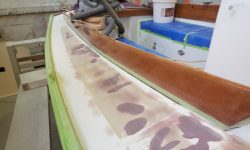

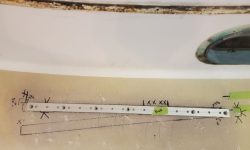

From belowdecks, using the pilotholes I drilled during the jib track layout, I drilled back up through the deck to redetermine the track position now that I’d filled and faired the deck above. For these purposes, I chose only to mark the forwardmost and aftermost holes on each side, which would be enough for me to recreate the tracks’ location later.

Similarly, I marked the holes for the cabintop handrails and, at the bow, the foredeck cleat.

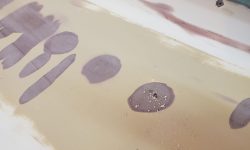

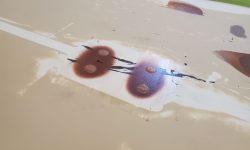

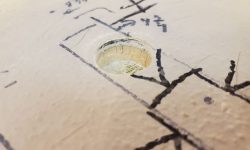

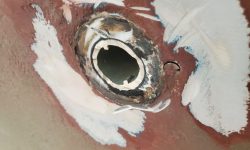

In the cabin, I sanded and prepared the damaged liner between the two scupper seacock locations, and also sanded clean the areas in way of each through hull for the new installations to come, and reamed out the existing hull holes to remove old sealant. For repainting purposes, I sanded clean the entire area aft of an existing wooden cleat to give me a defined and logical stopping point. Afterwards, I applied some epoxy filling compound to the liner.

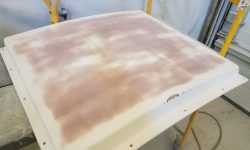

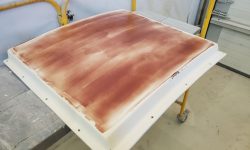

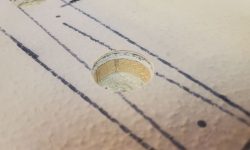

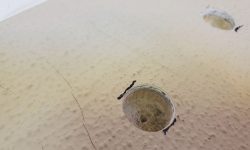

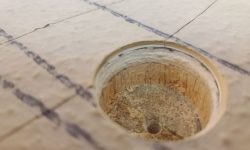

From a sheet of 3/4″ G10, I made up new backing blocks for the seacocks. I like to drill the large holes first, before cutting the sheet, to give me more clamping surface to hold the piece conveniently.

After a test-fit and final preparations, I installed the new blocks in a heavy bed of thickened and strengthened epoxy.

Total time billed on this job today: 6.5 hours

0600 Weather Observation: 38°, clearing. Forecast for the day: Clearing, 46°