Monday

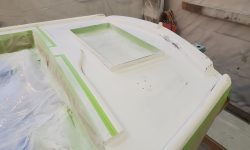

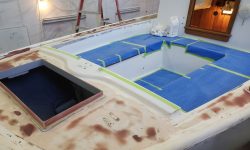

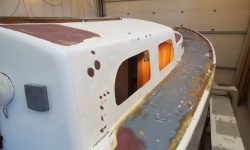

I spent the first part of the day going over the hull and deck once more, sanding the fine filler as needed by machine and hand, and retouching any other areas I found along the way. Where the new paint would intersect the “old” paint I’d applied in the cockpit during phase 1 a year before, at the aft ends of the cabin trunk and at the traveler platform, I removed an intentional and sacrificial piece of masking to expose a bit of the shiny paint (I’d previously masked right to the edge for the high-build), and now I sanded this transition smooth and remasked to prepare for the next layers of primer.

After the sanding, I blew down and vacuumed and solvent-washed the boat and shop to remove dust. This brought the surfaces to nearly their state of readiness for finish primer.

Afterwards I rinsed off the staging and floor to settle dust and clean these surfaces.

For finish primer, I planned to do the decks and hull in separate operations spread over two days, starting with the decks. I no longer wanted to adjust the staging in the midst of a spraying day, as I had sometimes done in the past, and while I’d managed to spray the high-build from the deck-height staging, it was not a process I cared to repeat for the much more important finish primer coats. With the substantial dual-round of sanding after high build, I could take some liberties with its application, but not so with the finish primer.

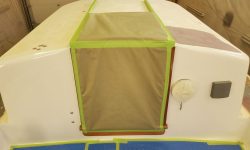

Because the deck primer and paint would cover the outside of the molded toerail down to the hull-deck seam, I masked off the hull just beneath to protect the prepared surfaces from overspray and make prepping and applying the hull primer easier the next day. I made a few minor masking repairs here and there on deck, then cleaned the entire deck once more with the proprietary solvent wash, leaving things ready for finish primer next time. Because I needed to get up on deck to better reach the centermost portions of the coachroof, I added some masking to the sidedeck so I could stand there without marring the clean deck beneath; once I sprayed the center portions, I’d remove that paper and spray the rest of the deck.

Total time billed on this job today: 7 hours

0600 Weather Observation: Fair, 12°. Forecast for the day: Chance of rain and snow , then rain and snow overnight, 36°