I was away from the shop for part of the morning on other business. When I returned, I began by installing the new battery platform in the port aft locker, though as of this writing I seemed to have no photos of this.

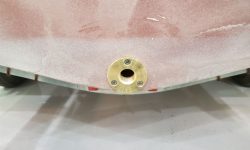

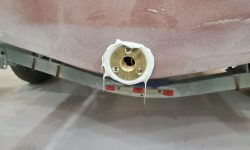

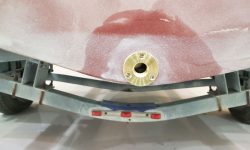

Next, I got to work on the livewell hatch installation, starting with drilling a 2″ hole for the latching hardware; I’d installed solid fiberglass in this area during the repairs. I installed the latch with new fasteners and butyl sealant. Afterwards, I installed the hatch in the boat and reinstalled the hinges, drilling and tapping for #10 machine screws in each location, with more butyl sealant. I had new gasket material for the hatch opening on order and would install it upon arrival.

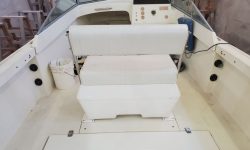

With the hatch reinstalled, I continued with the large cooler/pushmi-pullyu seat, located just forward of the hatch. This was a different unit than had originally been installed, but ’twas of little matter as I’d filled the old fastener holes before, and the new seat fit in more or less the same space and covered the old location entirely. After aligning the seat as desired, I installed it with new fasteners and butyl sealant. There were two pedestal-mount seats to be mounted behind the helm and console, but I planned to wait on these installations till I’d finished the wiring and other work at the helm.

With another boat arriving in a few days, and requiring the “real” side of the workshop, I took advantage of a nice afternoon to reposition the Holby in the other side of the shop, where I could continue working on the various remaining tasks on my list over the coming days and before the boat had to leave for the outboard dealer where the new powerplant would be rigged.

With the afternoon courier delivery of the new panel for the last section of the console, I finished up the day cutting and installing the final section. There’d be additional work on the console to install the switch panel and a flush-mount radio, both of which were now also on hand, and I looked forward to finishing up that work in the immediate future.