I lightly sanded the first coat of finish paint in the v-berth and head areas, then, after cleanup, applied the second and final coat.

Working carefully to avoid contact with any fresh paint, I removed the entire v-berth platform, which would allow me access to finish up work securing the water tank and painting the space, and also make it quick and easy to prime and paint the berth platform. While I had it apart, I took the opportunity to glue in some additional support cleats at the base of the small step area, which would eventually support cleats extending into the opening to hold the actual teak step in place.

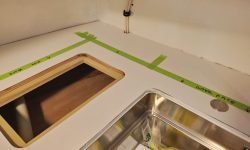

While I let the glue set up, I trimmed the refrigerator compartment lid according to the marks I’d made from the template. Happily, trimming the piece with its laminate in plate went smoothly, and soon I had the properly-fitting piece mounted in place. Final trim would later cover the exposed inboard edge, which was now a bit short by necessity since the adjacent countertop nearby dictated the overall width of the piece (this is what I’d had to trim).

After some final prep, masking (around the fiddles on the removable step piece), and setup, I applied primer to all the v-berth panels.

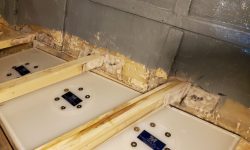

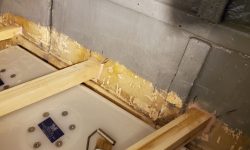

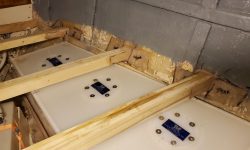

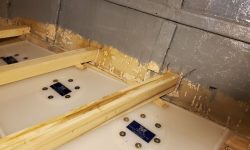

To help secure the water tank, I planned to use straps running longitudinally, since transverse straps proved to be challenging to engineer. I also planned to use solid bracing, well-cushioned against the tank itself, secured to the cross beams above, but that would come next time. In order to give the strap eyes required somewhere strong to mount, since there wasn’t room nor ability to through-bolt them to the water tank platform, I built two-piece plywood strips, with the strap eyes bolted to the outside piece, then the two sections epoxied together after milling recesses in the inside piece to provide clearance for the nuts (and held together as a unit with screws). Then, I secured these assemblies to the outside edges of the tank bulkheads with epoxy adhesive, leaving them alone to cure.

I spent the remainder of the afternoon working on milling various pieces of trim, including another length of fiddle trim required for the galley, two sections of trim designed for the mid-point of the settee backs, to cover the seam between upper and lower cabinets and also provide a lower fiddle for the open bookshelves, a piece of small general-purpose rounded flat trim, and several sections of cleat stock I’d need for the galley upper cabinet construction and elsewhere. I had many other pieces of trim to mill too, but I was still working out the final profiles required, so I took the pieces I had to final pre-installation completion by sanding them all smooth and applying a sealer coat of varnish.