Tuesday

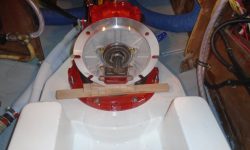

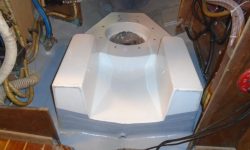

Thinking it would help me make the final minor adjustments needed to engage the transmission shaft and engine housing, I tried blocking the transmission into the proper orientation from the top side, where I could (I hoped) reach it conveniently and make adjustments as needed. Without the engine in place, the rubber gaskets of the leg allowed the transmission (and therefore the shaft) to sag forward a bit, and earlier I’d blocked the leg vertical from beneath the boat, but this meant various trips up and down the ladder to make an adjustment if needed. As it turned out, in practice I was unable to adjust the transmission position as I’d hoped, and eventually I removed the shims and reblocked the leg from the bottom of the hull as before.

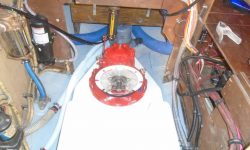

It took another hour or so to finally dial in the engine position and get the transmission shaft started in the engine receptacle. To make this happen, I had to block the engine from beneath the oil pan, supporting the aft end so I could remove the chain hoist; the hoist was preventing me from getting the engine into the right position. Then, with some incremental adjustments to the engine blocking and the drive leg blocking, as well as the angle of the engine and so forth, I finally clicked the shaft into position–a happy time. The job was made more complicated by the fact that I couldn’t actually see the point of required engagement, but once the two parts were mated none of the rest mattered any longer. For the edification of others and future reference, I found that the adjustable engine mounts at the forward end needed to be adjusted all the way down in order to align the engine and transmission.

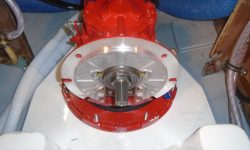

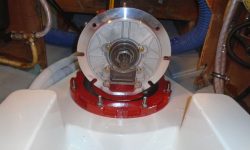

With the transmission engaged, it was quick work to bring the flanges properly together and install the fixing bolts.

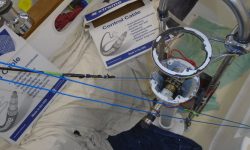

After a mid-day appointment, I returned to finish up securing the engine with the two flexible engine mounts at the forward end. These each required two bolts to secure them to the foundation. I planned to drill and tap the foundation to accept hex head bolts–nothing new there. As I drilled the first hole, I thought I saw metal chips, but initially wrote it off as shavings from the bit or perhaps the edge of the mount’s bolt hole. But it shortly became apparent that there was a metal plate embedded in the fiberglass foundation–stainless steel, no less. This was a fun surprise. No wonder the foundation had seemed heavier than it should.

I managed to drill and tap one of the four holes, but my tap–normally pressed into service in fiberglass only–was hardly up to the task of threading what seemed to be a 3/8″ or so thick stainless plate inside the fiberglass (it seemed to be the same thickness as the metal ring I’d installed for the transmission). I ordered new and better taps to arrive the next day, and this effectively ended my hopes of finishing up what had seemed a quick and simple task, as I elected to await my new tools before proceeding further with the bolts. Meanwhile, I took care of some preparations for the final installations I’d be wrapping up soon, now that the engine was finally in place.

Total time billed on this job today: 3.5 hours

0600 Weather Observation:

38°, partly cloudy. Forecast for the day: sun and increasing clouds, maybe 50.