Friday

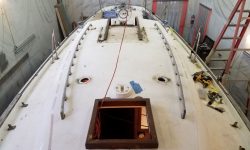

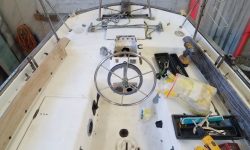

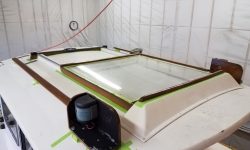

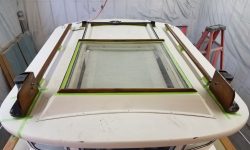

Working from above decks, I eased into the day with whatever hardware I could remove from the poop deck and around the lazarette (steering gear) hatch, starting with the hatch itself. To ease access to and fro, I removed the steering wheel, padding the end of the exposed shaft with a rag to avoid painful contact with the raw end.

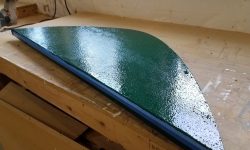

The lazarette hatch was in poor condition and would require some repair, and the piano hinge securing it was similarly poor, with rusted fasteners that eventually ceded to my removal demands; having the hatch out of the way eased access to the locker so I could remove the bolts securing the two center stern pulpit stanchions, along with a flagpole holder. I also removed some old hardware from the seat area above the helm (there was no cover for this and I planned to build one later), and a few installations in the cockpit well, including the engine instrument panel (which I’d previously noticed was already disconnected).

Next, I returned to the port cockpit locker to remove the remaining hardware from this side, including the port-side pulpit base, a mooring cleat, and the three chainplates. Two of the three chainplate locations here had already had their fiberglass sheathing removed at some point in the past, exposing the chainplates for relatively easy removal. The forwardmost chainplate still had its fiberglass in place over the chainplate, but by removing the nuts and hammering through the bolts, I more or less easily pushed the light tabbing away, allowing me to then rip it mostly free by hand. The chainplate beneath was corroded, and water ran out when I removed the fiberglass. Later, I’d return and further clean up the old glass, but for now I had the chainplate free and that’s what mattered.

To ease access to the furthest reaches of this locker, I removed the exhaust hose from its outlet, and then a tailpiece fitting, all of which cleared the way for me to reach the nuts securing the final hardware above. From there, it was relatively simple to remove whatever nuts I could from beneath and install vice-grips on the remainder so I could spin the fasteners off from above.

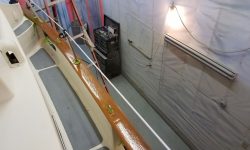

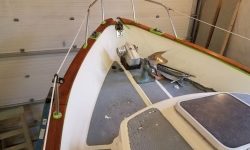

The starboard locker didn’t allow the same access, with the top of the quarterberth protruding, as well as some pumps and hoses at the aft end of the locker. To begin, I removed the locker lid and hinges here as well, then removed a horrible rusted old electrical box from the space. Then, I removed the final stanchion base, located just outboard and reachable from inside the locker.

Next, I turned to the coaming bolts. I could reach most of the nuts while reaching into the locker from the cockpit, and did so. The furthest bolt aft was out of reach, and since I wasn’t worried about salvaging the coamings, I thought nothing of grinding off the bolt head from outside and pushing through the stud; I also did this on a couple reluctant bolts in the winch island.

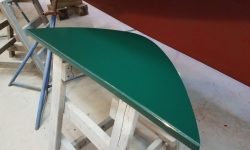

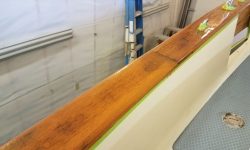

Afterwards, I easily pried the coaming away and removed it. I was pleased that the coamings had been removable with so much less effort than I’d anticipated.

I removed the bolts from the forward two sets of chainplates on this side, with a fair bit of effort and contorting. Unfortunately, I lost the center chainplate into the bilge somewhere when the last bolt, which I’d been fighting for some time (the holes in the chainplates and the knees themselves were small and held the bolts tightly), came free suddenly, and the chainplate dropped down out of the slot. This was annoying, but of little matter since it was clear all six of these after chainplates would require replacement. I couldn’t reach the aftermost chainplate from the cockpit and left it in place for the moment.

All that remained was the final pulpit base, a mooring cleat, and a couple small pieces of hardware on the starboard poop deck. Access to this area from beneath was theoretically possible by crawling from the port locker and through a narrow-ish passage between the aft end of the cockpit and the steering gear locker, but after considering it for a time–it was late in the day after a long week–I declined to crawl in there. Instead, I drilled out the fasteners for the remaining hardware from above, allowing me to remove all the hardware. I’d deal with the final chainplate another time, and would worry about reinstalling the hardware and the access here when the time came.

With the extended hardware removal stage now complete–much of it had been a fight–I looked forward to getting on with the deck inspection and repairs starting next time.

Total time billed on this job today: 7.25 hours

0600 Weather Observation: Partly clear, 20°. Forecast for the day: Sunny, 38°