April 15, 2020

Adeline 11

Wednesday

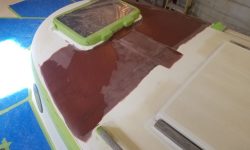

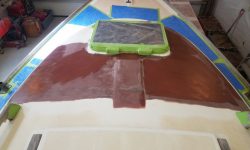

After another round of sanding, taking great care at the edges of the cabin trunk, the deck repair was approaching its final shape and finish, but there was still some fine-tuning required, between one known low spot to port and various minor troweling voids left from the edge work earlier.

After cleanup, remasking, and final prep, I applied additional fairing compound where needed, focusing on just a few areas where the additional work was required.

There was a bit of work I could do to advance the new mast hinge project, starting with drilling the mast base and the mast plug to accept a pin that would secure them together and prevent slippage while the mast was raised or lowered. We decided on a pin rather than screws or a bolt for its simplicity and effectiveness at doing the required job, as well as ease of installation and alignment. I didn’t have a pin on hand, but ordered the one I needed. Because of the existing boom vang bail on the base of the mast, which was right in the center of the spar, I had to drill the holes for the pin a bit forward of center.

With the mast base and plug drilled, I could install the plug on top of the new hinge. Since the flat mast platform on deck had not required any epoxy this go-round, I could dry-fit the hinge plate and check the basic alignment for the plug using my little template I’d made earlier. (I forgot to take pictures of this part of the process.) With masking tape atop the plate, I roughly aligned the hinge and mast plug as needed to ensure proper final positioning later, and made reference marks on the tape. Then, at the comfort of the bench, I fine-tuned the alignment of the mast plug and secured it to the top plate of the hinge with the two bolts supplied with the hinge; these bolts used hex spacers beneath the plate not only to secure the mast plug, but also to act as supports between the top and bottom plates, so the compressive force of the spar wasn’t bearing only on the top plate (though frankly the top plate seemed sturdy enough to support the spar in this case).

Once the deck work was complete, I’d permanently install the hinge plate to the deck in the appropriate position.

Meanwhile, I prepared a bit further for the ultimate installation. The new hinge plate required four bolts to secure it to the deck, and I planned to cut away part of the liner from beneath in order to gain access for nuts and washers, rather than try to work through small holes drilled in the liner the way it had been done originally. To cover the as-yet-uncut opening (I planned to wait to make the cut till I’d located and marked for the hinge plate bolts) once complete, and also because the liner in this area was badly cracked from the previous deck issues above, I decided to make a piece of teak trim that would cover the entire area in the passageway between the bulkheads, hiding not only the new opening, but the rest of the damaged liner in the area. I milled some leftover teak to the required dimensions and sanded it smooth and clean; there was no finish on any of the interior teak, so I planned to leave the new trim bare as well.

Total time billed on this job today: 3 hours

0600 Weather Observation: 35°, cloudy. Forecast for the day: Mostly cloudy, chance of a shower, 49°