April 21, 2016

Precision 2

Thursday

Getting ready to begin the project in earnest, I spent a short time aboard, documenting the initial condition of the boat and looking over the jobs list so I could begin to order any materials and parts required.

The biggest job, as it were, was the cockpit scuppers. The original scuppers used rigid plastic fittings and pipe to connect the cockpit well with the transom outlets, and these fittings had cracked over time, with several apparent attempts to stem the problem with sealant or other repairs apparent. The main issue with this situation was that access was essentially impossible for anyone other than a highly-skilled two year-old, as the molded interior structure and cockpit well prohibited direct access to the space from inside the boat–despite what looks like wide open access from the photos.

The answer to the access problem seemed to be to install a larger access hatch in the vertical section of the cockpit well, replacing the small round one. So creating this access would be the first part of the job, and afterwards hopefully the access would be sufficient to replace the fittings with a new system.

The interior cushions were badly worn and in poor condition, and I’d subcontracted their replacement to my trusted upholsterer. This job was already underway, and I removed the cushions from the boat to make more room for the other parts of the project.

The work list contained myriad and sundry smaller jobs, from rebedding the leaky chainplates to replacing the depthsounder to repairing some teak trim, among other things. I’d cover them all in more detail as the job got underway.

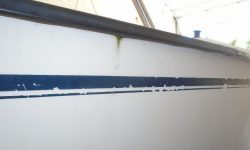

The hull would require some basic restorative work, including replacing the scuffed vinyl-tape bootstripe and painting the bottom.

Total time billed on this job today: .5 hours

0600 Weather Observation:

25°, clear. Forecast for the day: sunny, 70s