Monday

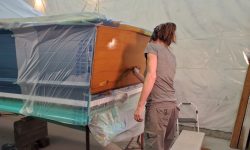

With the transom now ready, Renee was back to do the lettering, which would be gold leaf with a painted outline and would take two days.

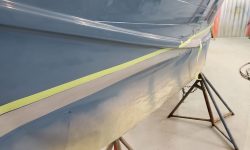

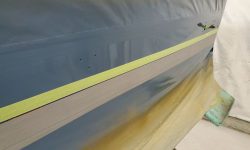

After initial layout, tracing the lettering outlines on the transom, and marking certain areas with masking tape (I missed most of this stage as I had to be away at a brief appointment), Renee applied sizing to the transom, brushing this on for each letter. The sizing is what holds the gold leaf in place.

Once the sizing tacked up sufficiently, it was time for the gold leaf, which is applied in small sheets and left proud of the lettering edges for now.

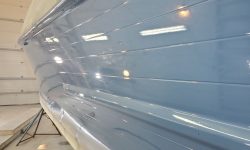

Once all the gold leaf was applied, she burnished it to remove the excess and provide some of the finished character to the leaf itself. This begins to highlight certain areas of the leaf and provide various visual tricks depending on the lighting and viewing angle.

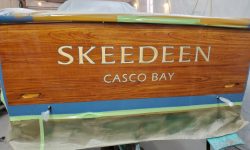

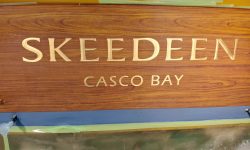

To enhance the appearance of the main lettering (name), the owner chose a convex burnished effect for the letters, which makes the lettering look carved or raised depending on the viewing angle and lighting. This is a deceptively simple effect created by burnishing roughly half the letters’ width in a particular pattern, using thin paper cutouts as guides, but the end result was amazingly convincing and would look even better later after the outline and then the final clearcoats were applied over the whole area.

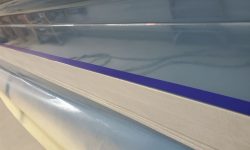

Some closeups of the completed gold leaf:

While this was going on, I worked in the woodshop to clean up the stainless steel half oval trim pieces from the boat, preparing them for reinstallation in the near future. I cleaned out old sealant from the back sides and polished the exteriors to remove surface rust.

Next, I worked on the various loose varnished trim pieces from the boat, which I’d previously prepped and sanded. Now, I applied the first of probably a couple coats of maintenance varnish to each.

Total time billed on this job today: 2 hours

0600 Weather Observation: 23°, cloudy. Forecast for the day: Cloudy and windy, showers, 42°