Thursday

The excess sealant around the ports had cured enough overnight to allow me to cut it away now and clean up the residue as needed, completing the ports’ installation.

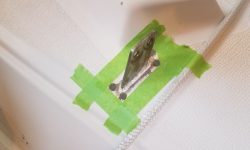

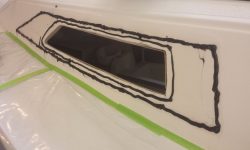

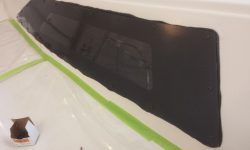

Next, I turned to the chainplates. The epoxy plugs at the fastener locations had cured overnight, so with the cover plates in position I drilled the new fastener holes: two pilot holes on the forward sides for the long sheet metal screws I’d use there, and two tapped holes for 8-32 machine screws at the after side. As usual, I milled little countersinks at the top of each hole, providng a little reservoir for excess sealant right at the fastener shank.

The portion of the chainplate slot through the deck was still well sealed with the polyurethane sealant I used when I rebedded them a year earlier, but this time I chose butyl tape sealant for the cover plates, covering the plate and fastener locations and wrapping more around the chainplate itself to help seal the slot. I hoped this highly flexible sealant would hold firm against the typical dynamic loads on these chainplates. I secured each plate with two long panhead #8 screws at the forward side, which penetrated the deck and into the bulkhead beneath, and a pair of 8-32 machine screws, washers and nuts at the aft ends.

Total time billed on this job today: 1.75 hours

0600 Weather Observation:

34°, cloudy. Forecast for the day: clouds, rain late in the afternoon and overnight