< Back to Halcyon

Wednesday

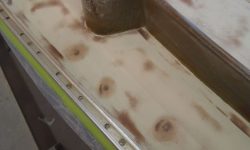

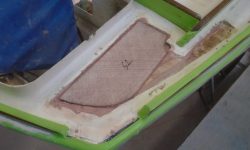

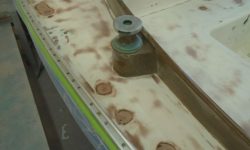

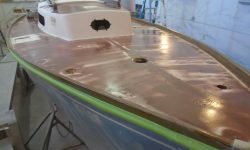

Finishing up the bottom work for now, I lightly water washed the new fairing patches, then sanded them smooth with the adjacent areas.

The bulk of my remaining work on this project would be on deck and in the cabin, as the owners had had the hull brushed a few years ago and were happy with the existing condition. So with hull work complete for now, I set up staging around the boat to give me a comfortable working height around the perimeter of the decks.

To protect the hull from spills or damage, I covered it with plastic that I taped to the top edge of the hull just outboard of the wooden toerails.

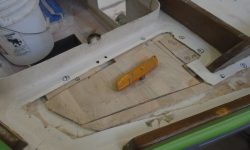

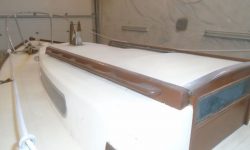

The decks were in original condition, generally fair in appearance but well worn, with thin and checked gelcoat and several areas where there were more significant cracks that could be indicative of structural damage. My scope of work for the decks in the weeks ahead included inspecting for and repairing any damage, and refinishing the entire deck in the usual way. These photos show the deck’s condition at this stage of the project.

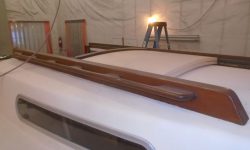

The exterior woodwork had been maintained for some time with Cetol wood finish, and was generally in fair or good condition, The current work list included applying a maintenance coat of finish to this wood, but I’d assess things further as time went on.

The interior appeared to be in original condition and in need of sprucing up, though at least most of the finishes were sound, if worn, tired, and dirty. The work plan here included repainting the overhead, hull, and other areas, refinishing much or all of the woodwork, and some additional work in the galley and “head” areas, along with revamping the basic electrical system, adding a GPS, and other maintenance tasks.

I removed all the contents of the cabin, storing it away for safekeeping for the duration of the project and, where needed, setting aside removable bits of woodwork, doors, cabin sole, etc. for later attention.

The original deck hardware–mainly aluminum with some bronze–was in fair condition overall, but several pieces were damaged or broken, including the port stern chock and stern cleat. I hoped to source original-specific replacements for the damaged hardware, and, if luck was with us, perhaps replace some of the other pieces–which were pitted if sound–if better vintage pieces turned up. These photos document the original placement and condition of the deck hardware. The original lifelines were in poor condition, and replacement (along with a rigging inspection and assessment) was on the list for the project.

With the basic preparations, unloading, and initial inspection complete, I was ready to get down to business, and would start removing deck hardware next time.

Total time billed on this job today: 6.5 hours

0600 Weather Observation:

32°, rain; freezing rain; sleet. Forecast for the day: precipitation ending, clearing,