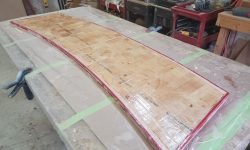

Beginning with the starboard side, I installed the coamings permanently. After removing the coamings from their varnishing supports and preparing installation tools and supplies, I dry-fit the starboard coaming, pressing it into place with my custom coaming press. Once the coaming was properly positioned, I temporarily installed it with a couple screws so I could then drill all the required screw holes in the proper places. Then, I removed the coaming so I could finish milling the fastener holes with a countersink, and otherwise prepare the area for final installation. Depending on access, I planned through bolts where I could, and screws for the remaining areas.

With the bonding areas cleaned up and prepared, I applied sealant to the screw holes and along the top edge of the cockpit, as well as at the leading and trailing edges where the coaming would rest. Then, I reinstalled the coaming a final time, securing it with screws and bolts as needed. Afterwards, I cleaned up the excess sealant, leaving a clean bead on the outer edges where the coaming met the deck and molded coaming block.

I repeated the process on the port side. Here, with several of the fasteners located over the quarterberth in the cabin, I was conscious of the interior liner, which was spaced about 3/8″ from the deck laminate itself–too far to support the fasteners properly. So with the coaming in place, I drilled pilot holes from the outside and all the way through the liner, then used a hole saw to cut 1-1/4″ openings in the liner at each location, allowing room for nuts and washers against the deck laminate, and sized to fit plastic cosmetic covers that I ordered and would fit once on hand. Once I’d drilled for all the fasteners, I removed the coaming, milled the fastener openings with a countersink, then reinstalled the coaming with sealant.

Later, I installed teak bungs in all the screw holes, securing them with waterproof wood glue.

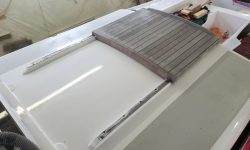

Next, I wanted to test-fit and pre-locate the new winch stands, particularly the forward set, to ensure the position was clear for the final dodger fitting scheduled for later in the week, but I also took the time to position the after set for later reference. These stands couldn’t be installed till the coaming varnish work was complete, but now was as good a time as any to determine their final locations based on the various reference measurements and deck construction details I’d made earlier in the project. The stands themselves wouldn’t stay in place without slipping on the deck angle, so I didn’t try to photograph them in position.

Varnish work on the coamings could continue once the sealant cured enough for masking, and once I had a chance to pare down the bungs.