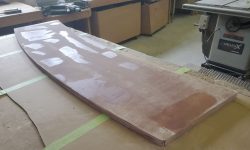

To install the latches and complete the hatch, I had to make a minor modification. The latches came with a stainless steel insert that was designed to work sort of like the retainers that hold gauges in thin metal panels–more of a clamp from the inside, with minimal designed overlap of the top flange. With the size hole I’d created, and the thickness of the hatch, I didn’t like how these were supposed to work: first because I’d have to fill and redrill the holes to a larger size to fit the insert; and second because if I did that, there’d be barely any flange overlapping the opening on the top (weather) side. Frankly, I couldn’t see how it would work anyway.

The fix was to use a short stainless steel bar, 1/8″ thick and 3″ long, to span the opening from the bottom side, and secure the top, operating part of the latch with screws through the little strap. This held the latch tightly in place and gave it at least a chance of an overlap to seal against the weather; even so, there was very little flange resting on the top of the hatch–but enough. I adjusted the height of the draw bars to approximate that of the cleats in the boat (using a scrap), but these might need adjustment later to accommodate the real world.

I’d get the hatch down to the boat and owner soon (relatively local), but now the project was truly complete from here.