I picked up some cheap 3/16″ plywood to use for building tank mockups and for other portions of the interior rebuild to come. With that on hand, I did some preparatory work in the forward cabin to clear the way for the new tank work, starting with disconnecting some wiring running across the aft end of the space, noting on each wire where it came from; I removed completely a wire running to the starboard stereo speaker, as this was straightforward and helped clear the passage into the forward space. Then, I removed the after three of the original cross beams that had supported the berth platform; these came out easily, as I had hoped, by cutting in the center and then pulling away the light tabbing that had secured them to the stringers at the hull on each side. These had to come out anyway, since the berth platform needed to be rebuilt and raised at the aft end to make it level.

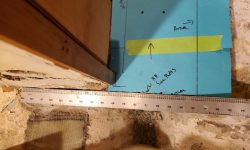

With the space as clear as possible for now, I began to work on the tank mockup. I started with a piece of plywood cut somewhat oversized, and representing the inboard edge of the tank, and used it to strike a line near the centerline of the boat but leaving room for access to the transducers mounted on the centerline. I installed some temporary hot-glue blocks to help hold the template, and added 3/8″ (9mm) scraps of plywood to stand in for an eventual small structural bulkhead that would help support the actual water tank in the final analysis.

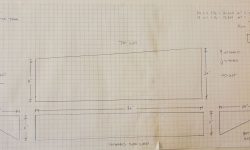

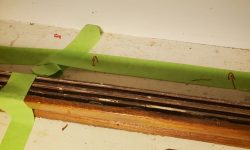

With a stick glued to the hull holding the panel plumb, I used a level to mark a vertical (plumb) line at the aft end, and also to mark a level line going forward at the correct height, keeping the top of the “tank” low enough to allow clearance beneath the eventual v-berth platform.

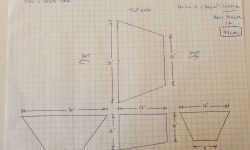

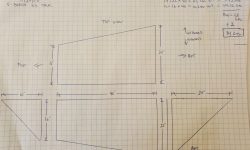

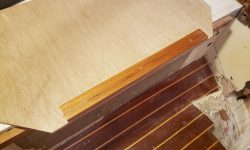

With the panel down on the bench, I cut along the marked lines, and transferred the plumb line forward to the forward end of the panel, creating a trapezoidal panel that fit along the hull and was plumb and level at the three remaining sides. Back in the boat, I set up and used temporary supports to hold the panel in the proper position.

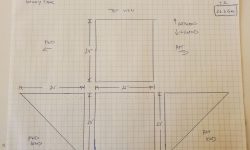

Now I used cardboard to make templates of the forward and after faces of the tank, making small modifications on the fly till I ended up with a 4-sided shape that maximized potential volume while staying away from the longitudinal stringers against the hull. I tested the aft face–the piece that would determine the largest three-dimensional size of the tank–to ensure it fit through the passage into the berth, as well as the companionway (it may not look like it fits through the companionway from the poor photo, but it does). Once I was satisfied with the cardboard templates, I transferred them to plywood and cut them out, with a final dry test-fit in the boat.

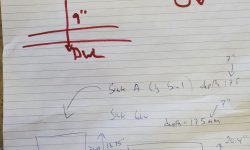

I removed the pieces down to the bench and assembled the ends and inboard panel with hot glue and cleats, then set the template upside down on the bench and secured it with cleats and screws so the three sides were square to one another and held firmly in place. I cut and installed support cleats along the edges to hold the final sides of the template flush with the ends, and laid out and cut a flat on the bottom corner of each end (4″ wide at the aft end, 2.5″ wide at the forward end). This flat not only gave the tank a bearing surface, but also helped with the layout of the angled outboard facets and maximizing volume along those edges.

This tank, as built, was somewhat larger than the original measurements I’d taken earlier, in part because the overall length is longer, the tank is a bit taller, and also because of the two-sided outboard edge. As of this writing I’d not had a chance to calculate approximate volume but would do so once I could measure the final result.

Before the end of the day, I had time to lay out and cut the narrow flat bottom of the tank, which would ultimately rest on a small platform built into the boat for the purpose. I’d finish up the mockup next time.