Tuesday

Late last week, we had a meeting at the boat to look at and discuss details of the dodger installation. To prepare for that meeting, I set up a quick analog for the boom height, which was the critical factor in determining the dodger height. After measuring to the gooseneck location on the mast, and allowing for the depth of the boom below its attachment point, I mocked up the setup with a 2×4 acting as the mast, and a string (which I led to the closest wall and leveled it) to represent the bottom of the boom in a horizontal position.

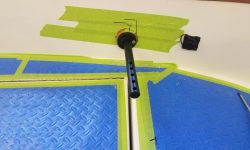

The net outcome of the meeting was that the owner decided against building the dodger. The boom height was lower than any of us thought, and the dodger would have been quite small and confining. This would have been workable if need be, but the owner had his own doubts about the project from the getgo: while the dodger would be nice to have sometimes, the way he used the boat didn’t demand having one, and usually didn’t need it at all. With all this, the deciding factor in abandoning the dodger project was the new rigid boom vang the owner had ordered and that we planned to install at the shop. The new vang would extend far enough aft that it could have its own effect on the dodger design, and this ended up being the straw that broke the camel’s back.

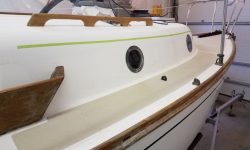

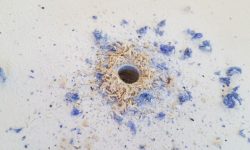

With that behind us, and after a day finishing up some details on another project at the shop, I got back to things with the cockpit coamings. I’d already stripped (but not sanded) the old coating from the insides of the coamings, and now I worked on the outside faces. First, though, I decided to remove the old sheet winches, which were slated for replacement with new self-tailing ones during this project, and with the winches out of the way I’d have slightly better access for stripping and sanding the wood. These were easy to remove, and I took a moment to test-fit one of the new winches, which were slightly larger in overall diameter but still just within the footprint of the existing bronze winch bases, though the drums slightly overhung the edges. I’d discuss this with the owner before proceeding, but the new winches seemed workable without major changes.

With that, I got to work removing the old coating from the outside of the coamings on both sides. As before, this took some time because of the thinness of the coating and the character/texture of the wood beneath, which was somewhat weathered with much of the wood’s softer grain being long gone with the passage of time, leaving behind the slightly uneven and hard surface we associate with aged, weathered teak.

Afterwards, I sanded the coamings clean and smooth in all areas, working through 80-120 grits to bring them to their final appearance. These would be left bare to weather naturally from here on out, along with all the other woodwork on deck. The nature of the existing woodgrain meant that some texture remained in the coamings, as they had long ago weathered past the point of glassiness, but the clean appearance would soon weather evenly to match the texture.

With the coamings stripped and sanded, I could reinstall the various bronze coaming cleats I’d removed at the onset of the job. On the port side, there had been two of these cleats all along, though the after one had been installed without the little bronze backing plate like its brethren. Now, I reinstalled this cleat with a new backing plate to match its counterpart. On the starboard side, there’d been only a single cleat, and the owner asked me to install a second one to match the port, which I did now. The new cleat to starboard would give the owner a good place to secure the roller furling line, which meant that I could remove the lame hoseclamped-on plastic cleat from the nearby stern pulpit, which had been the previous setup.

I recommended a spirited sail on a choppy day to splash the new bronze–and the bare teak–with salt water to begin and accelerate the aging process and desired patina.

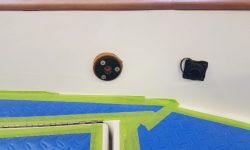

After final preparations, I painted the underside of the sea hood, the first step towards preparing it for its final installation.

Total time billed on this job today: 6 hours (including Friday)

0600 Weather Observation: 28°, cloudy. Forecast for the day: Snow and rain showers, 35°