Wednesday

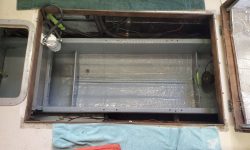

The morning dissolved into a series of unplanned events that prohibited production, including preparing for a boat delivery later in the day, minor equipment failures, paint delivery that required collating, and an unexpected errand to pick up a special can of paint for the transom, but with all that out of the way I looked forward to getting started on the hull prep.

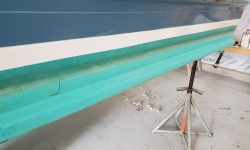

Before beginning, I made some reference marks so I could recreate the waterline (i.e. top of the bottom paint) if necessary. The boottop had a scribe mark delineating its top edge, but I couldn’t see one at the bottom edge, so to be safe I used a simple wooden gauge to mark a set distance down from the waterline, which would make it easy enough to restrike the line later. As it happened, I later found that there was indeed a second scribe mark (on the grassy knoll), but that’s getting just a bit ahead of things.

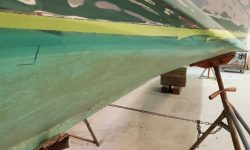

The hull was in good condition overall, and the existing coating was Awlgrip, so the existing surface would provide a good substrate with minimal preparation. Because I was pretty sure the hull had been polished or even waxed at some point, I started with a solvent wash to decontaminate the surface. Afterwards, starting at the starboard bow, I sanded the hull with 120 grit paper and a palm sander, scuffing the surface and removing gloss. I planned to follow with additional sanding and 220 grit later, but for now I concentrated on the single grit.

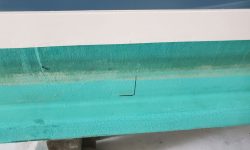

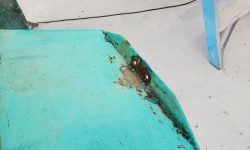

At the waterline, I used a more aggressive tool to remove most of the boottop paint–several layers of one-part white over a red layer of undetermined nature–and then finished up with the palm sander. Now I discovered the lower scribe mark, which had simply been filled with paint and not immediately visible. This meant my reference marks were mostly erroneous.

During the course of the afternoon session, I sanded the entire starboard side and transom in this manner. By about halfway down the hull, I’d discovered that the palm sander, held at an angle in the simulated plank lines, would do a fair job of deglossing the paint in those tight recesses, which I’d been struggling with by hand up till then. Next time, I’d finish up the initial sanding on the port side, and later rounds of sanding with finer paper would complete the job. Repairs and other prep work promised to be minimal thanks to the good condition of the hull.

Total time billed on this job today: 5 hours

0600 Weather Observation: 55°, overcast. Forecast for the day: Overcast, chance of showers, 66°