Monday

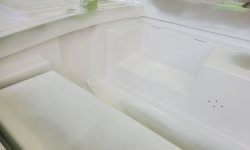

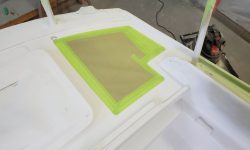

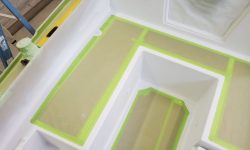

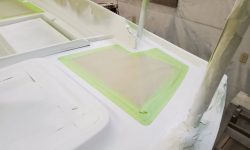

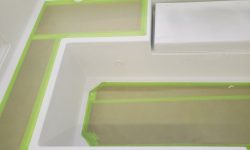

To prepare for the final topcoats in the cockpit, I laid out and masked off the eventual nonskid field areas, leaving a 1-1/2″ border around the edges in most areas. At the locker lid openings, I reduced this to 3/4″ at the adjacent edges so that a corresponding 3/4″ border on the lids themselves would complete and make up the visual 1-1/2″ border. I covered the field areas with masking paper to protect against overspray.

I put the lids temporarily in place while I marked and masked the borders against the cockpit well, so that the border would be straight and consistent between the lids and adjacent cockpit faces, but I finished up the masking down on the bench. I didn’t mask off a nonskid area on the lazarette hatch since most of this hatch would be covered by the permanently-attached solar panel, and I saw no reason for the textured surface there, but nonskid could easily be added to this hatch in the future if desired.

With the decks prepared, I moved on to the hull. Though I wouldn’t be able to spray the cockpit and hull on the same day this time around because I couldn’t risk overspray from the hull besmirching the cockpit paint (this hadn’t mattered during primer steps), I still wanted all the hull prep complete so it would be ready to go the day after the cockpit.

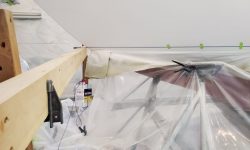

The final hull prep centered around the new boottop. Here, the owners requested that I leave a narrow strip of hull color between the boot and the bottom, which is a nice look, so this required striking two new lines to demark the bottom and top edges of the new stripe. With a level across the cockpit seats, I confirmed that the boat was still level from side to side and that the painting and sanding work hadn’t shifted things at all.

To begin, I used a small level, straightedge, and two marking blocks (3/4″ and 2″ thick, respectively) to transfer the existing, and newly-struck, waterline (top of the bottom paint) marks at stem and stern 3/4″ higher for the lower edge (leaving a 3/4″ visual border), and 2″ above that for the visual thickness of the new boottop.

With the new marks for reference at the stem and stern, I set up my horizontal crossbeams at the first, lower mark and, after leveling both, set up my string and, as before, marked the lower edge of the boottop along both sides of the hull. This mark would leave a visually 3/4″ wide border of hull color beneath the boottop.

Moving the beams temporarily while resetting them to the height of the upper edge of the boottop gave me time and opportunity to mask off the lower edge along the pencil marks I’d made during the layout. With that complete, I reset the beams 2″ above the lower mark, creating a stripe that would be 2″ wide amidships.

With the layout complete, I masked off the top edge of the new stripe, following the tick marks on the hull. At the bow, I increased the height at the stem by about 3/4″, and flared the top edge of the stripe along the forward third or so of the boat, to a point roughly 6′ aft on each side, chosen more or less randomly but by eye. This subtle flare improved appearance by offsetting the eye’s tendency to see the stripe as narrower at the bow because of the shape of the hull and sheerline there.

With the top and bottom edges masked and defined, I filled in between with more masking tape.

With all masking complete, I finished up with day with a final solvent wash of deck and hull, along with paint, lighting, and equipment preparations for the cockpit topcoats next time.

Total time billed on this job today: 8 hours

0600 Weather Observation: 27°, cloudy. Forecast for the day: Cloudy with chance of snow showers, 34°