Wednesday

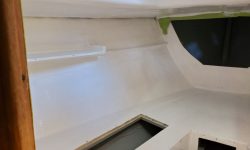

For the bilge and utility locker spaces, the owner requested a lighter version of the usual gray bilge paint, so I mixed up a 50/50 mix using a gallon each of white and gray to considerably lighten the color. With the paint mixed, I got to work on beginning the interior paint, starting at the bow in the chainlocker.

Continuing aft, I painted the lockers beneath the V-berth, and around the water tank to the extent possible, before painting the first section of bilge on my way out.

Next, I painted the storage lockers on both sides of the head compartment, and the bilge there as well.

In the main cabin, I painted what I could reach through the various locker openings in the tops and sides of the settees, and the bilges.

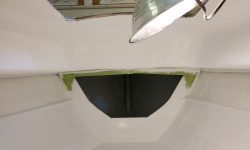

Starting with the space beneath the cockpit on the centerline, as far aft as I could reach, I painted everything below cockpit level and through the engine room, including the forward face of the cockpit well.

To finish up for now, I painted the hull inside the port and starboard cockpit lockers, from just forward of the lazarette up to and including the aft-facing sides of the engine room bulkhead. The lazarette still had some work to go, so I held off painting in there for now.

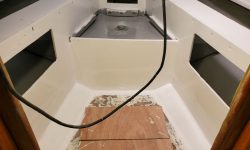

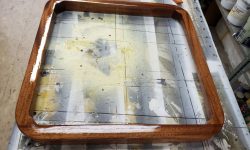

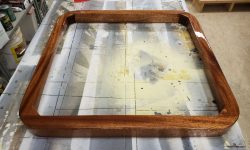

During the afternoon, I turned my attention to that very lazarette as I continued work on the storage arrangements for the small generator. After various test-fits and puzzling things out, I started working on a support platform for the generator that could accommodate it without raising headroom too much. Beginning with the cardboard template I’d made of the generator footprint, after some adjustments for hull shape I transitioned to a template made from some scrap 1/4″ plywood. The new platform would require an angled installation, and the forward end would ultimately be supported against the back side of the cockpit well, but at the moment there was a fiberglass arrangement there in the way (though it did sort of help support my platform templates for now), and I couldn’t remove the fiberglass because I didn’t want to disturb the nearby fresh locker paint, so I worked around it.

Various reference marks I made on the hull and cockpit, along with side views courtesy of the camera held through the cockpit locker openings, helped me start to figure out how the platform would need to work. In these photos, the template is still too low at the cockpit end, but once I could start doing dirty work in the space I could and would made adjustments there and add the requisite supports to hold the platform more where it needed to be to support the generator. In this orientation, the handle at the top of the generator was just flush with the deck above, which meant that it would be clear beneath the new hatch once built. Other details, like chocks, fiddles, and means of securing the generator, would easily work themselves out once the basic platform idea came together.

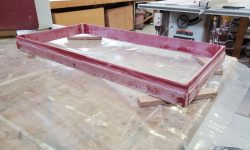

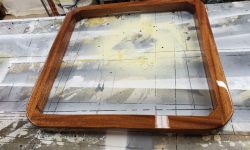

Eventually happy with my plywood template, I used it to cut a real floor from some marine plywood. I beveled the aft edge severely to help it fit against the shape of the hull and counter at the aft end. I had time to test-fit the platform, but I had one more thing I wanted to do before the end of the day, so that was all for the generator at the moment.

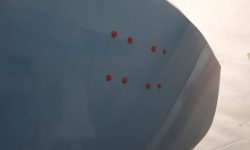

There was a series of holes in the transom leftover from a long-ago outboard bracket, and now I made preparations to fill them. After reaming them out with a large countersink from outside, I cleaned everything up and masked inside and out before filling the holes with epoxy fairing compound. I removed the exterior tape once the fill was in place. With some delicate finish work once the epoxy cured, I’d be able to touch up the paint with something close to the paint that was on the hull.

With the remains of the fairing compound, I troweled over that little line in the middle of the aft cockpit patch.

Total time billed on this job today: 7 hours

0600 Weather Observation: 16°, clear. Forecast for the day: Sunny, 24°