Friday

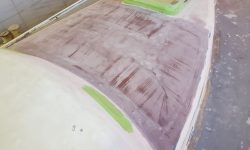

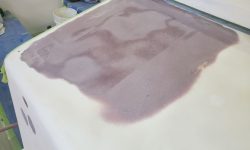

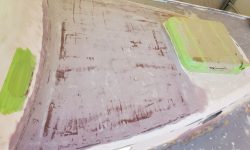

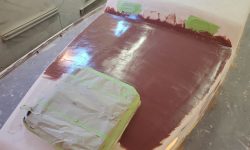

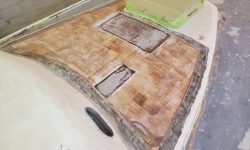

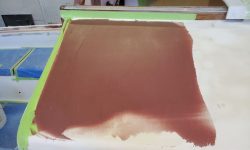

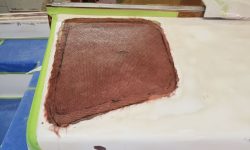

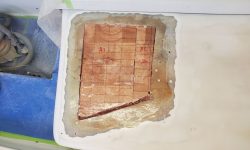

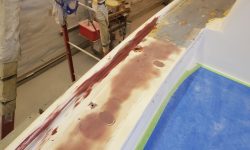

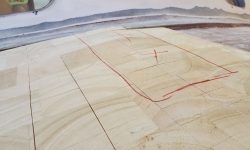

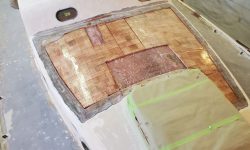

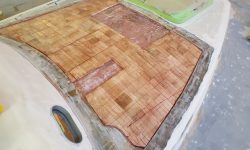

Beginning once more on deck, I finish-sanded the coachroof recore project, now for the last time this go-round. I was pretty pleased with the end results but once the high-build primer was on I was sure there’d be a few pinholes and minor additional filling needed.

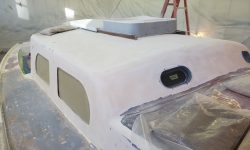

And just like that, it was time to transition into primer prep for real. I began this with a significant cleanup of the boat and shop: Blowing down the boat and walls; vacuuming the boat inside and out; sweeping; and, since I planned to dismantle the staging and reinstall it at deck height again, took the opportunity to solvent-wash the hull first. Finally, I rinsed off the staging and floor to settle the remaining dust. Clear air once more.

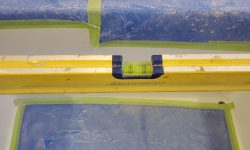

Before moving back up to deck level to begin the final primer preparations there, I checked again the boat’s level and found it a bit off; I’d found a loose stand before and so it wasn’t a surprise that things had shifted a bit. So I made the requisite adjustments to bring the boat back to level (side to side).

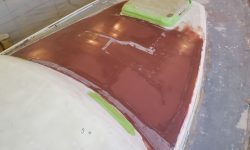

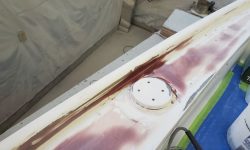

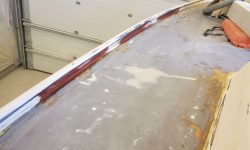

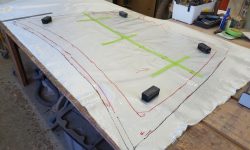

While the staging was in limbo, it was a great time to mark the waterline (in this case meaning the upper edge of the bottom paint, or lower edge of the hull paint to come). When I’d made my reference measurements before beginning hull paint removal, I’d pre-determined and measured for the new line, so now it was pretty simple matter to recreate these marks at the stem (40″ down from the bottom of the chainplate) and stern (18.5″ from the transom corner at the centerline). I set up horizontal (level) beams stem and stern at these heights.

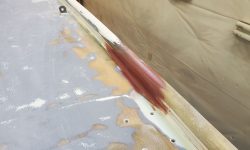

With a string tautly suspended between the two beams, I marked the new line, starting roughly amidships (or at maximum beam) and, bit by bit, bringing the string into touch the hull, taping it in place and making pencil marks above, starting first with the aft half (till the string reached the centerline at the counter), then from amidships forward to the stem in the same way, and repeating the processes on the other side of the boat.

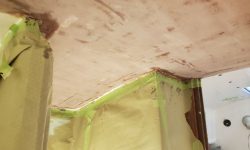

After removing the paraphernalia, I masked to the pencil marks, fairing by eye and delineating the area to be primed above. By now it was late in the day, and with the floor still wet in places I decided to await installing my habitual strip of masking paper beneath the tape till next time.

Total time billed on this job today: 6.5 hours

0600 Weather Observation: 19°, mostly cloudy. Forecast for the day: Mostly cloudy, 30°