To start the day, I made an early trip to the machine shop to pick up the new chainplates and backing plates.

Over the weekend, the owner and I discussed relocating the fresh water pump from its existing location in the galley, which he said was hard to access, to the forward cabin, where the new water tank would be. This would also simplify the plumbing, and extending the wiring would be straightforward. In my mind I remembered enough room for the pump there, so I decided to go ahead first thing and move the pump to its new location.

First, I used a long level to mark the aft bulkhead in the v-berth with the proper level height, as the original had been several inches too low at the aft end. I transferred the new mark across the bulkhead on each side to give me a reference point for how much room there was available. There was enough room outboard of the existing washdown pump already located there to mount the fresh water pump, while still staying clear of the eventual berth structure and the other pump and maintaining access for hoses, filter changes, etc. For now, I mounted the pump and its associated wiring terminal; I’d extend the existing wires forward another time.

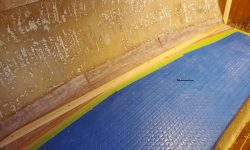

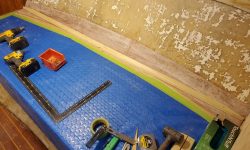

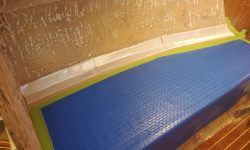

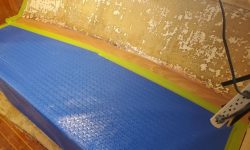

Now I turned to the final installation of the settee backrests with glue and screws.

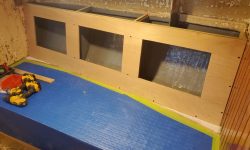

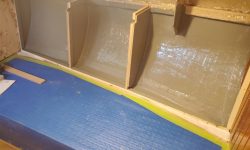

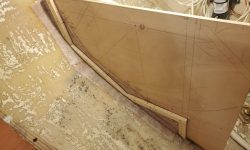

With those permanently in place, I made some basic measurements and cut rough patterns for the top shelves from 3/16″ plywood, then scribed and adjusted these as needed till I was satisfied with the templates.

I transferred the shapes to the 12mm plywood and cut out the shelves, leaving them a bit wide to overhang the backrests for now and making minor adjustments as needed till the shelves fit properly. I marked the overhangs for trimming.

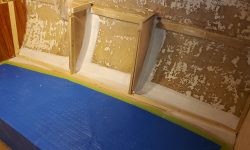

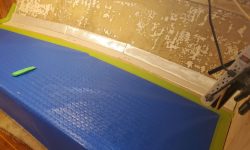

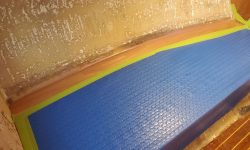

Down on the bench, I trimmed the overhangs and enlarged somewhat the openings around the chainplate knees to allow room for the chainplates and bolting access, then installed the shelves permanently with glue and screws on all the support cleats I’d previously installed, and epoxy along the hull edge. Then, I installed a strip of 4″ tabbing to help secure the shelf all along the hull.

This brought things to the end of the day; I’d continue next time with the upper cabinets.