Tuesday

I began the day as per usual with sanding and varnish for the loose hatches (4th coat).

I continued–and completed–the removal of the old windlass cable, including the solenoid in the hanging locker and another small control wire that went with it. For ease of removal, I’d planned to cut the cable into smaller sections, but my old cutters weren’t up to the job, so after struggling with one set of cuts I pulled the rest of the cable out whole. Overall the cable had been in fair condition, but new cable would be better and of higher quality, as the original cable was not tinned and was less flexible than the good marine cable. At a few places where the cable disappeared behind lockers, I pulled through a length of messenger line to make installing the new cable that much easier.

Afterwards, I removed some old wire ties and mounts from the chainlocker, and removed the original foot switch to make way for the new pair that I’d be installing along with the new windlass. I finalized the order for installation materials and cable for the new windlass, so that would be along soon so I could continue the initial parts of the installation then.

Next, I reinstalled the various bits of hardware I’d removed for the exterior varnish project, using mainly new (and mostly bronze) fasteners to replace the originals.

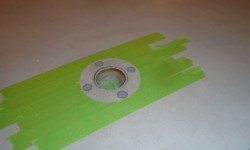

During a session of what he’d hoped would be routine stuffing box maintenance, the owner discovered that the stuffing box hose was in less-than-ideal condition, with rusty clamps and a suspect appearance. Coupled with the fact that the old packing deep in the nut was highly compressed and impossible to move, he decided, with my input, that we should go ahead and replace the stuffing box hose, which would also allow repacking of the existing packing box down on the bench since replacing the hose would require removal of the propeller shaft. This job had been on and off the theoretical work list a couple times so far, but now it was clear the path that was required.

Access to this area, other than the convenient way I could hold a camera from the engine room to photograph the shaft and stuffing box above, was limited to a tight crawl space beneath the cockpit, which required the flexibility (and size) of a gymnast. Permanent cabinets around the engine room prohibited access from there, and while I’d already been in both cockpit lockers a few times during earlier stages of the project, I was pessimistic about the prospects of gaining realistic access to the shaft myself.

Nonetheless, I determined to try. Access into the cockpit locker was pretty good, but maneuvering space within was quite limited by the placement of two bulkheads and a large seacock, and once there, while I thought that theoretically I could get myself into the cozy space on top of the battery shelf, which was required in order to see–and work on–the shaft and coupling, ultimately I decided that it’d be more efficient and prudent to call upon a helper to work in the space, so I made arrangements for a few days hence and in the meantime planned to collect the new materials required so we could complete the job on one sitting.

To mollify myself, I went ahead and removed the propeller so that the shaft would be free to move aft as required for the rest of the job. The shaft zinc, nuts, and propeller came off without drama nor issue.

Total time billed on this job today: 5 hours

0600 Weather Report:

35°, mostly cloudy. Forecast for the day: clearing, colder, high around 38