January 27, 2016

lh2

Wednesday

I got started with the new bilge pump automatic switch, a high-end float switch in a sealed containment. Given the space availabilty and access to the bilge, and the way the switch could be mounted with its supplied mounting hardware, I chose to install the switch on a piece of narrow fiberglass flat stock to make mounting straightforward and retrieval of the switch easy. I clamped the cylindrical switch to the stock after first cutting the fiberglass to length after a test-fit in the engine room, and led its wiring up the stick, securing it as necessary. At the lower end, I added some chafing bear since the whole arrangement would be very near the stuffing box once installed.

With the switch mounted and wires in place, I installed the stick and switch in the bilge, at the aft end next to the shaft, and secured the mounting stick with two screws into a convenient plywood support member above. Then, I made up the various wires–five in all–to interconnect the bilge pump and switch with the wiring to the boat’s bilge pump switch at the helm.

With the wiring complete, I tested the pump. The auto switch could be tested by inverting it, but it also came with a little green indicator light on the top of the switch to show that it was properly wired in the automatic position. When switched to manual, the pump operated well.

One thing about these pumps is they don’t differentiate the wiring (two black wires) or inlet/outlet, since wiring one way versus the other would change the inlet/outlet position as it changed the direction of the pump motor. I determined the flow direction of the pump–as wired–during the pump test, and marked the inlet and outlet myself for future reference. Then, I attached a length of 3/4″ hose, along with the supplied strainer, to the inlet, running the suction end well aft into shaft alley. The outlet end required an adapter to fit the 1-1/8″ hose that was already in place to the transom through hull, so I didn’t make this connection at the moment as I didn’t have the fitting on hand.

With the bilge pump complete for all intents and purposes, I turned again to the new engine room blower. The plan for the outlet for the blower was to lead it through the defunct built-in propane locker and out a vent from there into the cockpit. To maintain use of this locker as much as possible, we decided to use a length of rigid pipe installed through the locker floor, which would minimize fragile hose runs. To this end, I drilled a large hole in the bottom of the locker (after ensuring the way was clear beneath) to accommodate the 4″fiberglass tubing.

At the aft side of the locker, I drilled another large hole in which I mounted a louvered vent fitting to extend the discharge out into the cockpit. I installed the louvers with sealant and bolts, only using the bolts because it made it easier to install in this location since access was tight with the new propane locker just behind.

After cutting a 12″ piece of the fiberglass tubing, I tacked it in place inside the new hole in the locker with hot glue. Because the blue vent hose I chose was a tight fit on this tubing, I pre-installed two lengths of the hose before I installed the pipe, as it was easier to do on the bench than in this tight locker. Once the hot glue had dried and was holding the pipe securely enough, I mixed some thickened epoxy for fillet material, and, later, installed fiberglass tabbing all the way around the pipe to secure it to the boat. Before these steps I’d sanded clean the bonding surfaces in the locker. I left the fiberglass to cure.

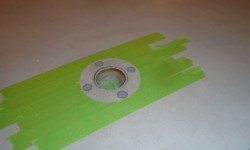

The owner had a solar panel that he elected to mount on the pilothouse roof, and its installation details were next on my list. It was late in the day, so to begin, I prepared to install a through-deck wiring lead for the panel wires, and after making some reference marks and removing a section of the cosmetic overhead in the cabin, I drilled a large-ish hole through the overhead, then reamed out the core from within its opening and around the fastener locations, and filled these voids with thickened epoxy to isolate the core through these penetrations. I left this to cure before continuing the process.

Total time billed on this job today: 6.75 hours

0600 Weather Report:

32°, cloudy. Forecast for the day: Mainly cloudy, highs in the 40s but dropping during the afternoon