Monday

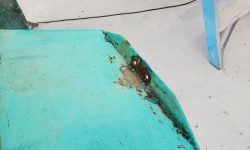

After a light sanding, I deemed the two through hull patches complete. Sometime later I’d seal the fairing compound with some plain epoxy, but for now the work was done.

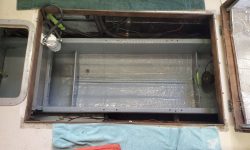

After final preparations and masking, I applied a coat of gray bilge paint to the engine room and battery compartment, bringing the fresh paint up to and including the tops of the stringers.

Over the weekend, I’d thought that with some luck I could probably remove the remaining swim platform fasteners and brackets with a socket and long extensions. Fortunately I had ample extra extensions around so I could assemble the length I needed to reach the nuts at the transom from the nearby (but not near enough) deck hatches. By taping the ratchet handle in place to the deck and hatch covers as needed, I could go outside the boat and remove the screws one by one, resetting the extension setup for each of the three nuts on both sides. It took a while and plenty of backs and forths, but it worked.

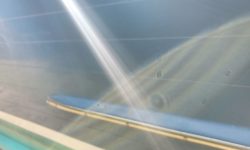

Next, I unscrewed the tops of the trim tab cylinders, which allowed me to pull out the hoses enough to undo the compression nuts holding them in place. I masked over the open ends of the connectors on both sides, and later removed the cylinders from the tabs themselves, a straightforward operation that got them out of the way for the work ahead.

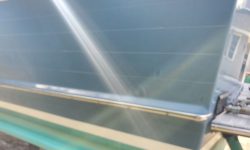

The only hardware remaining on the hull for me to remove now was the stern light fixture and a half oval trim on the stem, both of which I removed and set aside. With just a few final decisions and lingering jobs on deck, it wouldn’t be long before I could start the hull prep in earnest.

For the moment, there wasn’t much more to do on the hull till I could wrap and mask up the decks, so for now I filled the rest of the day by removing some of the brightwork trim from the cockpit (companionway hatches, rodholders, and the cockpit lower edge trims on both sides and transom–not shown here). With brightwork maintenance on the list for later in the project, I could work on some of these loose pieces during natural slow times throughout the painting process, particularly once the work on the faux teak transom and lettering began.

Total time billed on this job today: 5.25 hours

0600 Weather Observation: 50°, overcast, foggy. Forecast for the day: Becoming sunny, 65°