Thursday

With a small grinder, I opened up various existing gouges and small cracks or voids that I’d noted on the topsides, preparing them for filling. After solvent-washing as required, I applied a coat of epoxy fairing compound to these areas.

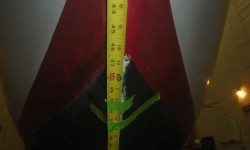

Preparing the keel ballast areas for refairing, I determined a need to open up the two areas on the port side a bit more, as I found loose material at the edges of the areas I’d ground out before. So I pulled out the old fairing material and ground these areas back to sound material, and brightened up the exposed lead to prepare it for epoxy-coating and first round fairing compound, which I applied in turn once I’d thoroughly cleaned the newly-ground areas.

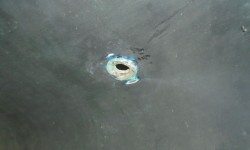

Meanwhile, I sanded the inside of the knotmeter patch area, and, after cleaning, masked over the opening in the bilge so I could fill the hole from outside with a thickened epoxy mixture. After a while, the epoxy plug had cured enough to allow me to install layers of biaxial fiberglass on the outside and, later, on the inside, once I removed the tape.

I also took a moment to fill and patch with fiberglass two erroneous holes someone (ahem) had drilled in the keel deadwood while searching for the actual bilge sump to drain the water at the onset of the project. The third hole, which was in the right location, would later become a larger hole to accommodate a bronze garboard drain.

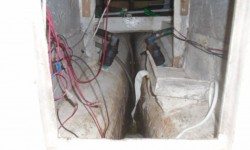

With the hull work well underway for now, I turned to the interior. The scope of work in the cabin for the moment was to clean up most of the areas and leave as is, as the molded liner and forward cabin areas were mainly just neglected and dirty, and the owner had minimal plans for actually using the interior. However, the overhead in the main cabin, including the cabin trunk, quarter berths, and other areas down as far as the full-length shelves on each side, required more work to bring back to acceptable condition, with poorly-applied and peeling paint, and the remnants of the old plywood and vinyl overhead system.

So after first removing the long teak fiddles from the shelves, to allow better access for prep and paint work, I spent the afternoon preparing these areas for new primer and paint, sanding away the failing paint and scuffing all areas. The old resin and mat that had actually stuck to the overhead where the old panels had been was recalcitrant to remove, but I eventually prevailed, as prevail I must.

Total time billed on this job today: 7 Hours

0600 Weather Report:

48°, partly clear. Forecast for the day: partly sunny, windy, about 60°, drying out from 6-8″ rain on 9/30