Wednesday

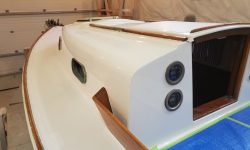

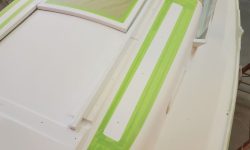

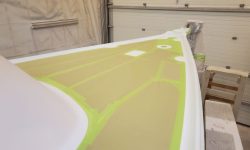

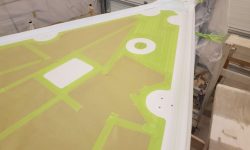

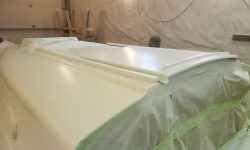

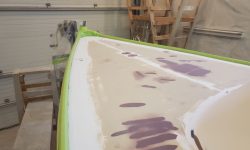

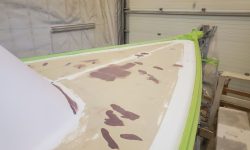

After cleaning up and putting away the spray equipment, I spent the remainder of the morning removing all the masking tape and paper from the decks, leaving the plastic sheeting in place over the hull for now to maintain protection during the next few jobs on board. The fresh paint would require another day’s cure time before I could tape over it to prepare for the nonskid.

In the afternoon, I turned to the settee fronts. Earlier, I’d determined that piece of teak plywood I had on hand was just a bit too short for these fronts, but after some discussion the owner and I decided that extending the plywood slightly with glued-on solid wood would be an acceptable and preferable treatment here. I’d originally though of adding solid wood to each end of the panel, but the owner requested that we do it all at the aft end, which was fine with me.

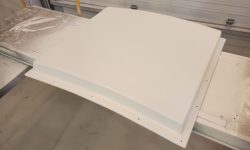

Using the old panels as templates, I laid out and cut the two new panels from the 1/2″ teak plywood. The panels were approximately 2″ shorter than required, so from scrap teak I made up slightly oversized blocks to glue to the aft end of each panel. The solid pieces were a bit thinner than the plywood, as it was what I had available in the appropriate width and the way the original panels were made the aft ends were sculped away on the back sides anyway, where they met the molded fiberglass liner, so most of any thicker material would have been removed anyway. I didn’t have any clamps long enough to span the lengths of the panels with their extensions, so I worked out a way to clamp the wood in place atop a flat panel that I’d covered with plastic to ensure that the face was absolutely flush. I left the glue to cure overnight, and would finish shaping and dimensioning the panels next time.

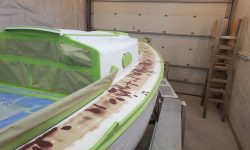

The original eyebrow trim from the cabin trunk could have been reused, as it had come off cleanly enough, though it had been sanded down enough over the years that there was no longer any depth for bungs (and all the bungs but one had been missing when I removed the trim earlier), so even before removal we had long ago decided that it made more sense in any case to simply mill new trim when the time came.

The time was now, and from some teak offcuts of appropriate size I milled two new pieces to fit. Basing the profile off the originals, but thicker to allow room for bungs, I milled the narrow pieces about 3/4″ wide with a 10° angle on the top and 5° angle on the bottom edge, then, after cutting to length, sanded the new trim smooth and rounded over the edges. I marked and drilled counterbores for bungs and pilot holes for fasteners, then, before leaving for the day, applied a first coat of finish to all sides of the new trim.

Total time billed on this job today: 6.5 hours

0600 Weather Observation: 24°, partly clear. Forecast for the day: Increasing clouds, then light snow likely in the afternoon, 27°