Monday

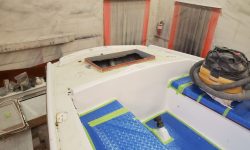

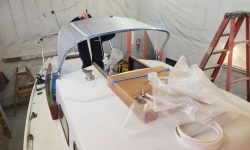

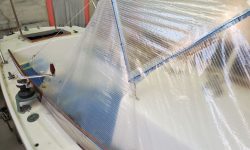

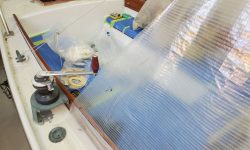

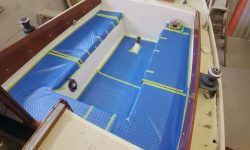

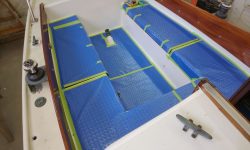

Preparing for the deck work ahead (mainly a thorough cosmetic overhaul, but the forward coachroof was soft and required recoring), my first task, as usual, was to remove deck hardware. In this case, I’d only just installed the hardware six or seven months earlier, during phase 1 of the project, so removal went smoothly and quickly since the fasteners were still new and access was quite good in most parts of the boat; even areas with blind access were easy enough to reach.

During the course of the day, I removed all the deck hardware, starting in the stern and cockpit with the pulpit, cleats, winch bases, and cockpit coamings. I was surprised at how well the thin strip of butyl tape I’d installed behind the coamings held: With all fasteners removed the coamings didn’t budge from their curves. It was quite stretchy when finally released. I also found that the sealant I used on the bulk of the deck hardware held firmly as well, but released well enough once I got it started. Since on this boat the existing deck paint was in poor condition with serious adhesion problems–the main reason for the work ahead–the paint often failed when in way of the hardware removals. I’d actually never had opportunity to dismantle anything I’d installed over the years, so it was interesting to gauge the efficacy of the various sealants.

Moving on, I went to the bow and started working aft from there, removing the bow pulpit, anchor roller, mooring bitt, chocks, cowl vent, and spinnaker pole chocks. Then, I finished up the bulk of the deck hardware with the genoa tracks, stanchion bases, chainplate covers, and main halyard gear on the coachroof (winch, cleat, and fairlead). In all cases, I could easily remove the nuts from belowdecks (none of the fasteners spun in place, thanks to the combination of newness, good sealant, and the threaded deck holes), then remove the fasteners from above. This all made the process go inordinately quickly. I saved all the fasteners I could for reuse, as most were in like-new condition; I’d specifically chosen not to cut off any excess bolt length during the original installation so that I might be able to reuse the fasteners now.

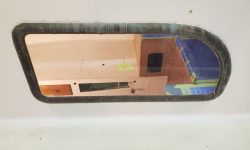

Next, I removed the deadlights from the main cabin, taking care to note any fasteners that were different from the rest. Most were of consistent length, but there were a couple shorter ones, and one longer one, plus two bolt/washer/nut combinations I’d had to use on the starboard forward light since I couldn’t get the machine screws to grab otherwise. I hoped and planned to correct these during the fresh installation ahead. All four installations appeared well bedded once I’d removed the inner frames.

Removal of the outer frames was not difficult; I planned to leave the lenses in place and intact for the reinstallation, as all were well-installed from a few months earlier and there was no reason to think of replacing them.

Still ahead were the small opening ports, and the mast step, but for now the day was done.

Total time billed on this job today: 6 hours

0600 Weather Observation: Fair, 17°. Forecast for the day: Sunny, 20°