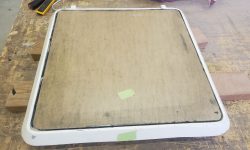

The first order of business on the pedestal was to remove a huge Velcro pad, to which had been secured a winch handle pocket. This Velcro was well-stuck to the side of the pedestal with its integral adhesive, and removal was challenging; then, it left behind a mass of gummy adhesive that I could only remove by scraping, taking some of the pedestal coating with it. Once that was off and scraped clean, I thoroughly sanded the pedestal as needed, feathering out areas where the paint had flaked clean through to the aluminum beneath so that the final result would have an acceptably smooth appearance.

Ideally, it would have been nice to strip the pedestal fully down to raw aluminum and recoat with a series of appropriate etching metal primers and so forth, but that was impracticable with the pedestal mounted in the boat, and doing the job right would be uneconomical. So as before, when I refinished the pedestal in 2016, I settled for “good enough”. With all the old coating now gone from the pedestal base–the worst part of the pedestal then and now–I hoped that the new paint would adhere better and last longer, though the pedestal would require occasional recoating for best appearance going forward. If this were to be a once every 10 years sort of thing, that seemed reasonable enough.

To that end, I found some metal primer in my inventory left over from some other job long forgotten, and since it was what I had, I decided to use it on the bare metal parts as a good base before priming the entire thing anew. I planned to let the metal primer cure over the weekend, and then over a few additional days I could apply regular primer and two or three coats of new white paint.