Following a productive meeting with the owner at the boat on Saturday, I now had more clear direction on the project scope, and was ready to get to work.

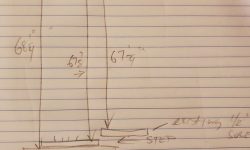

To begin, I addressed some questions the owner had had after our meeting, starting with some investigative measurements with the forward lower chainplates. There were knees installed belowdecks, but forward lowers had never been installed to the best of the owner’s knowledge, and he hoped to replace an existing babystay with forward lowers during this refit. The spar maker required a minimum distance of 15.75″ (400mm) forward of the mast (whether forward edge of the mast or mast centerline was not determined) for these to be effective. The way the knees were situated didn’t allow me to easily make this measurement from belowdecks, so I transferred the knees’ positions to the deck and, with a string led between the marks across the deck, made the necessary measurement. I used the forward edge of the mast collar as my reference, as if the minimum measurement was satisfied there, at the forwardmost point, it would surely be acceptable by any standard. With over 16″ available from these criteria, the forward chainplates appeared to be properly positioned as needed (aad also the same distance forward of the center chainplates as the after ones were aft, which is typical).

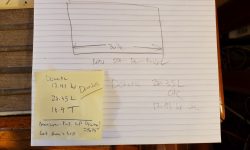

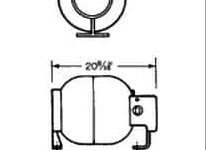

Next, the owner sent me some specifications on an electric portable refrigerator he hoped to use in the refurbished galley, with the idea of placing it under what was currently the nav station desk. To that end, I measured the space to confirm that the dimensions would work: they would, with some relatively minor relocation of some of the electrical components currently installed in the space.

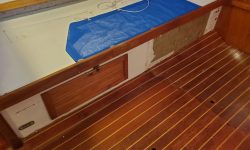

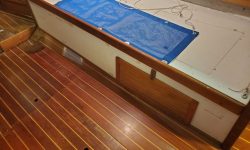

The owner had concerns about the existing mast step for the keel-stepped spar. This was some sort of aluminum fabrication, the details of which were unknown, but portions were visible on either end of the space, and the aluminum showed signs of ongoing corrosion and deterioration. At first glance, the step appeared to be a solid and massive mass of aluminum, which seemed unlikely, but in any event the owner was keen to rebuilt the structure. The nearby cabin sole was well-rotted and I pulled away some large sections by hand to provide better access to the step area for these photos (later I removed the rest of the sole from the head to expose all of the area in question). I documented the existing condition of the step and its installation before beginning any demolition or investigative work.

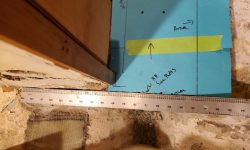

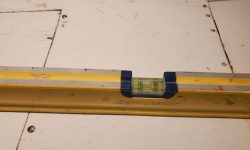

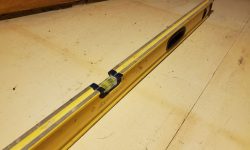

Next, I measured and documented the position of the step in various ways, including its height (measured from a known criterion at the mast collar) and longitudinal and transverse positions. The distance from the deck to the top of the step structure, as well as the mast base fitting itself, were critical for proper reconstruction later. I used a straightedge to transfer some of the measurements to nearby structural members for later reference and easier re-creation. Then, I dismantled some of the nearby woodwork–specifically the outboard side of a wooden mast enclosure and a replacement panel on the aft edge of the bulkhead–to clear the way for some of the work ahead. Sometime later, I’d make a template of the area, specifically to help relocate the mast base hardware.

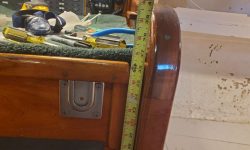

The slotted hardware that accepted the base of the mast, when stepped, was secured to the aluminum step structure with four machine screws that I removed without any trouble.

Before going much further, I paused to bail out some water that remained in the bilge on either side of the step, and also to remove the cabin heater for safekeeping and to remove it from what would soon become a dusty environment.

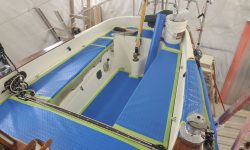

I didn’t know what I was going to find next, but I started working around the exposed part of the aluminum step to probe the nearby fiberglass and see if I could figure out the edges and limits of what, at this point, still appeared to be one huge solid block on the centerline. Since most of the step was exposed towards the starboard side, I started there and soon defined a clear, straight edge, from which I could pry up the nearby fiberglass (to starboard) with several prying-type tools. By now, I’d managed to determine that beneath this tabbing, there was softer material, at least between the forward and after edges, and it was starting to look like the structure featured two vertical webs (spanning the width of the hull fore and aft) incorporating the center, main, part of the step. The tabbing, despite being loose, was too thick for me to pry up by hand, so I got myself set up with breathing supply, tools, and other protective gear and cut away the fiberglass with an angle grinder and cutoff wheel. This exposed the starboard side of the structure and revealed expanding foam filling the void between the transverse webs of the step. The foam was intact, but wet.

Now I spent the remainder of the day digging out the foam and making some additional cuts in the tabbing here and there, now that the nature of the structure was more clear. With the foam removed, the “solid” center mass of the step became a 1/2″ or 3/4″ horizontal top plate with a vertical web beneath, running to the hull along the centerline, all interconnected with the hull-shaped transverse webs on either end, roughly 12″ apart. The aluminum, despite its appearance and some obvious deterioration, was sound to the extent possible to determine. By the end of the day, I’d cleaned up the starboard side pretty well, including cutting some of the tabbing on each end that once secured the web, and had made some cuts on the port side (where the structure passed beneath the main bulkhead and into the head), but dismantling that portion would wait till next time.