Wednesday

With several factors affecting the decision on the windlass–whether to replace or postpone–I wanted to look more closely at the existing power cable runs to ensure that the wires were worthy of being reused. Finding the unkempt and disconnected ends in the port cockpit locker a while back had made it seem prudent to inspect the entire length before committing to using them, or determining whether they should be replaced. Regardless of the condition of the main runs, the aft end would require some attention and extensions, and the existing ends in the chainlocker, while generally serviceable, were limited in length and whether they’d be able to properly reach a new windlass configuration remained up in the air for the moment.

During earlier portions of the project, I’d already removed some trim and cover panels in the forward cabin and head, which gave me access to the wiring in those spaces. Now I removed the cover panels along the port side of the saloon to expose the final length of the cables for inspection. I didn’t see any issues with the cabling through these runs.

Checking the cable in a short span that ran through a locker at the aft end of the port settee, I discovered–unexpectedly–the solenoid control switch for the old windlass. I suppose it was mounted here with the idea that it was a safe, dry spot for the unit, though typically one finds them mounted near the windlass motor to limit wire runs from the solenoid to the control switches. Any new windlass would require a different solenoid control anyway, and the access to this unit would be challenging thanks to the tightness of the locker and especially because of the protruding electrical box that blocked direct access–visual and otherwise–to the solenoid. But all that was something that could be dealt with as required.

So the core wiring looked acceptable, though not without caveats. The ends would require work, and the cable would need to be conjoined in the center where the solenoid currently was.

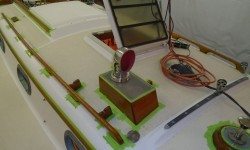

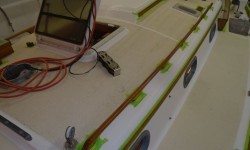

Meanwhile, I removed another access panel on the starboard side, this time to give me access to the underside of the toerails. The reason I needed this was to add extra lengths of genoa track to the toerail above, to extend the existing tracks forward. The owner reported that the position of the existing tracks was too far aft to properly lead the headsail he was using–I think the position of the tracks envisioned a very high-clew yankee-type sail–so in the near future I’d be adding lengths and bolting them through the toerail. I’d extend the tracks up to just aft of the mid-rail chocks, which would give nearly five extra feet of length for better sail control. I had the tracks on hand but would wait to give the new varnish work plenty of cure time before installing them.

I spent the bulk of the day removing the masking tape from the exterior brightwork, which I was calling complete with my habitual six base coats. I thought it was a vast improvement over the initial appearance.

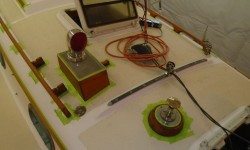

With the largest single project now behind me, I could start focusing on the laundry list of other tasks planned for this boat, most of which I’d been thinking about and considering behind the scenes throughout the past days. The new genoa tracks were one of these projects, and another was to inspect–and, if necessary, deal with–the deck around a bronze inspection port over the rudder post in the cockpit. There were a few cracks running through the deck emanating from the inspection port, and the owner wanted me to check whether there were any issues within.

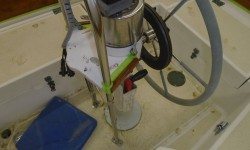

I didn’t have a tool on hand to fit the holes in the deck plate (there was probably one on board the boat), but I had no trouble opening the nicely-greased bronze threads with a pair of Philips screwdrivers. My initial inspection didn’t find anything of particular concern–the core seemed OK where accessible, and the deck sound– but if needed or desired I could remove the deck plate for core-edge protection and rebedding.

An old bronze vent on the transom, servicing the waste tank, was heavily corroded, and the owner requested replacement. To gain better access, I removed one of the cowl vents on the poop deck, and with a new vent already on hand I’d take care of the replacement presently.

Total time billed on this job today: 5.75 hours

0600 Weather Report:

20°, clear. Forecast for the day: Sunny and windy, highs in the 20s